|

|

|

|

|

Build Log

Peter Rake's Yak Air-1

Yes, I know - I was going to slow down on my builds but I'd promised Pete some time ago that I'd do a prototype build of the little Air-1 - Alexandr Yakovlev's first powered aircraft. Yakovlev was working as a labourer in the Russian Air Academy in the mid 1920's but his passion for airplanes led him to use his spare time and money to design and build his own plane. Helped and scorned by some of the Academy staff, the little biplane was built, well documented and test flown with no apparent vices. It later made a long distance trip from Sevastapol to Moscow, 1240 km, non-stop - a world record. Yakovlev was later accepted at the Academy as a student and the rest is history! From humble gliders and the AIR-1 in the mid '20s through various military aircraft in WW2 and on to vertical takeoff jets in the '60s, the Yak name was known world wide. Yakovlev died in 1989.

The AIR-1 (btw, the AIR name stands for a mentor - A I RIKO!) was heavily influenced by Geoffrey DeHavilland who's DH 60 Moth was known to Yakovlev. The aircraft was powered by a Cirrus engine purchased with borrowed and begged money by Yakovlev. Next - Peter's model Pat |

|

|

|

|

|

|

|

|

|

|

Peter's model of the AIR-1 is to 1/8 scale and spans around 43". The very simple structure may make it suitable for a first or second scratch build - it has a fairly long nose so balance shouldn't be a problem, and minimal power should be required to fly what I would think as a 24-32 oz model.

Although the plan shows a cheap 'bell' motor, I may fit a park 450 - the same as my BE12. There is limited space under the cowl so size IS important  I've chosen the AIR-1 configuration for its world record distance run - the forward cockpit was filled with a fuel tank and closed over - I hope Pete doesn't mind. The covering will be Litespan - either white or cream. The original was clear doped linen over open frames and ply giving a dirty whitish look to the aircraft. The wheels on the record-breaking machine were aluminium. The little model has a simple box fuselage with sheet covered turtle deck and soft balsa cowl. The cowl was polished aluminium - I'll try some silvery film for that. The only complicated bit is the rather exposed, upright Cirrus aircooled engine - at 1/8 scale, I'd like it to be simple but convincing - it forms part of the access hatch and should not be too fragile. The box of bits from Manzano was the usual crisply cut bunch of ply, bass and balsa we have come to expect and should form the basis of a simple but elegant little biplane. Now to tidy the bench, put a few projects away and start building  Pat |

|

|

|

|

|

|

|

|

neat litttle plane Pat, just remember your mantra above for the build... if you want we can record it onto a tape or cd and you can have it playing in the background like some sort of building cadence

Craig |

|

|

|

|

|

|

|

|

A Start on the Fuselage..

Since this will probably be a fairly quiet thread (the subject is not as alluring as a Moth or Camel

) and it may be of interest to someone looking for a simple first biplane build, I'll try to do the build in a step-by-step manner with a few more basic comments and photos than I might normally have. That's the plan anyway! ) and it may be of interest to someone looking for a simple first biplane build, I'll try to do the build in a step-by-step manner with a few more basic comments and photos than I might normally have. That's the plan anyway!After a giving the drawings a good going over (several times), I cut most of the strip wood from sheet stock. I'll try to make a list of the extra stuff in case anyone is interested. My trusty Master Airscrew stripper did the job. The fuselage is very basic - a square box with some rounded formers on top, sheet balsa turtle-deck (the rounded top) and chunks of soft balsa block around the front. The longerons were stripped from semi-hard 1/8 balsa, and together with the sheet forward parts, used to form two fuselage sides. Titebond glue holds it together. The second frame was built over the first with cling-flim between. The tail end should be made a few mm (5?) longer than the side view as they lose some length when pulled into the rudder post later (I always forget that). Check the actual longeron length from the top view. When the glue was cured, the frames were clamped together and gently sanded to ensure they were identical. The top edge should be completely flat. The cutouts for the UC cross pieces were deepened as the 1/8 ply was closer to 4mm - a common problem. Each frame was then carefully sanded on both sides with a long sanding bar to get them of consistant thickness and remove glue lumps and the little control cable exits were added. With two almost identical frames, they will next be formed into a box. I say almost - one side has a foot-step cutout - this will be on the port or left side. I choose hard balsa by its colour - usually with conspicuous darker grain marks, and its stiffness. But try not to break too may sheets in the store - you may be asked to leave! Pat |

|

|

Last edited by Pat Lynch; Oct 08, 2010 at 10:11 PM.

|

|

|

|

|

|

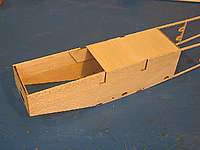

I made a box!

Before starting to make a box, the two cheeks or backing plates were added to the fuselage insides. These form sockets for the centre-section struts to be added later. I set these plates 1.5mm below the top edge to create a rebate for the cockpit 'floor' later.

BTW, I've found it handy to mark parts 'up..down..left..right..inside etc' where this may be useful later on. F1 and F4 - two 1/8 ply parts, may look straightforward but F1 has the motor hole to the left and up, while F4 is not quite square - be careful  With one side pinned flat on the board, F1 and F4 were glued in line with the ends of the sheet sides and exactly vertical then allowed to dry. A couple of good squares are very handy. Then the other side is glued on top of F1 and F4 checking for alignment at all points around the frame - esp. the tail end. A weight placed on top will help make a good joint. The two ply UC cross pieces were lightly epoxied in place and when cured, the cockpit floor and underside fill-in pieces of 1/16 (1.5mm) sheet were added with the grain cross-wise. Making this strong box will prevent the front deforming when the rear is pulled together. The balsa fill-in parts were fixed using medium CA. The box was now given a thorough sanding with a sanding bar, to ensure all surfaces are flush, free of glue lumps and looking good  Pat (getting back to basics) |

|

|

Last edited by Pat Lynch; Oct 08, 2010 at 10:13 PM.

|

|

|

|

|

|

Interesting how similar that is to the Pietenpol that I am building. Another simple build.

charlie |

|

|

|

|

|

||

|

|

Quote:

It's so simple a design, it almost doesn't look Russian... James |

|

|

|

||

|

|

|

|

|

More Fuselage....

The next task was to pull the rear frames together at the rudder post and fit all the cross pieces. Using the top view of the plan, all the 1/8 sq. cross pieces were cut in pairs with their ends angled to match the sides and placed to one side. With the basic 'box' all glued together and dry, a small centre mark was made on the top and bottom edges of F1 and F4. the box was then pinned over the protected plan with the two formers lined up exactly on the plan centre-line.

The tail skid support, TS, was pinned temporarily in postion over the plan while the two sides were carefully pulled together at the rear. After cutting to exactly the required length, the inside edges of the rudder post uprights were chamfered to make a good joint and clamped together - not glued. The various cross pieces for the top side of the fuselage (the part on the plan) were glued in place and clamped/pinned as required. These may not line up exactly with the uprights because of the curvature of the sides. But they should be as marked to support the top half-formers correctly later. With those in place, the bottom 1/8 sq cross parts can be glued in place, flush with the lower longerons. While all this is drying, the TS plate can be removed from the plan and glued between the lower longerons. While fixing all the X-pieces in place, I continually checked the fuselage sides to be square with plan. I deliberately didn't glue the two rudder post uprights together yet as the back end angle is different to the sides. The rear join should be exactly vertical over the plan before gluing and clamping and everything left to cure. When happy that it was dry, the frame was removed, checked for any twists (there weren't) and then lightly sanded to give smooth even surfaces all round. Note that the Yak does NOT have a smoothly curving top profile - the longerons curve after leaving the sheet sides, run straight to the TS plate, then curve again into the rudder post. It can look a bit wasp-waisted at some angles. Now the fun bit can start  Pat |

|

|

Last edited by Pat Lynch; Oct 09, 2010 at 12:29 AM.

|

|

|

|

|

|

Craig, James - I think the simplicity is what appealed to me. I was in a lull after the Bison build last year and Pete asked if I'd be interested in the YAK. A simple 'no-brainer' seemed like a good idea at the time! Well, things seldom turn out as expected and I did the Be12a, an F2b and the Ansaldo before getting to this little beast (?). Now, with life a bit more stable, a nice, quiet AIR-1 is just the ticket

Notice I'm also using Titebond instead of CA - makes me take longer breaks..... Notice I'm also using Titebond instead of CA - makes me take longer breaks.....Pat |

|

|

|

|

|

|

|

|

Matt - the shadow you can see on the top wing is a Tigermoth-style fuel tank. It should be a quickish build because it is so simple - no subribs etc.

The only bit I'm pondering is the aluminium cowl. Larry used some nice metallic film on a recent model and it looked good. The real thing was apparently, 'engine turned' like this photo - this replica looks like the rigging isn't working too well! Pat |

|

|

|

|

|

||

|

|

Quote:

I've seen DIY videos (YouTube, large gorgeous Pup) but getting the look is pretty labor intensive. I think Spikkkkk did it to an Eindecker. I like the Krylon Aluminum paint, but it's pretty dead. I'm sure whatever you do will look the part and then some. Since this model will likely be quite attractive to the relative novice, are you using that as a constraint in detailing? If so, I applaud your restraint...though the build is young.

|

|

|

|

||

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Build Log | Peter Rake 1/6 Scale Albatros DVa | hammerd | Scale Kit/Scratch Built | 927 | Oct 29, 2017 02:17 PM |

| Build Log | Peter Rake-designed 30" Verville Air Coach (Prototype Build) | Deuce | Scale Kit/Scratch Built | 58 | May 31, 2012 07:10 PM |

| Build Log | Peter Rake's Fokker F.II - 30" Prototype Build | gupi | Scale Kit/Scratch Built | 115 | Nov 20, 2011 05:59 PM |

| Build Log | Peter Rake's 30" General Western Meteor Prototype | dz1sfb | Scale Kit/Scratch Built | 19 | Aug 15, 2010 10:38 PM |

| Discussion | Peter Rake's Sopwith 1.5 Strutter -but brushless | parf | Scale Kit/Scratch Built | 8 | Jan 11, 2010 06:47 AM |