|

|

|

|

|

Discussion

What? Another Elliot Bay launch?

howdy folks..

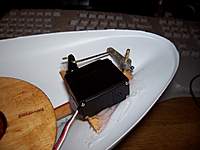

as i said previously in Kmots build log, I'm building my second elliot bay and taking a lot of my previous experience, and a lot of what he went through to put out an even finer model. I also went on to say that I planned to make it transitional. as in, I want to make a cap for it.. eventually that will mimic the prototypes "hunters cabin" option. and use that to hide electrics for a swappable electric conversion. like I said.. that's eventual. right now I'm concentrating on making it per the kit and steam, but I'm designing in the eventual swappable electrical conversion. the hunters cabin is a bolt on kit from elliot bay and doesn't modify the original build or hull in any way. so it makes sense to build as steam first IMHO. So to begin with.. I've assembled, stained and PU'd the wooden sub structure. I've been taking a lot of time with this so its been a couple of weeks of messing around with that.. my first model was slapped together on a tv tray in the living room of my old apartment. i have a garage, workshop, and a little more room to spread out and take time this time. as you can see in the pic below, the hull parts are ready to be mated. as per KMOTS build log, I'll be useing solvent plastic cement and NOT CA for the mating. in fact, I'm taking the scrap material from triming the hull to build up the lip to take the glue. Before I do that however, I will be installing 6/40 blind nuts at the engine mount holes so I dont have to worry about stripping out wood when I go to switch out power plants. Also, I will be lighting the deck. through my other, other, other hobby of computer harvesting, I have a set of micro red and green LEDs and some ultra bright white LEDs. the red and greens will be mounted forward as navigation lights of course. I intend to replace the rear flag mast with a short length of 1/16th id copper or brass tubing and mounting a white LED to that. the positive anode of the LED running through the tube with the negative soldered to the OD of the tube, with all LED connections going to a breadboard culminating with LEDs in the eventual cabin. A single 9volt battery should be more that adequate for everything but its going to meen mounting and wireing everything before mating the halves. and making sure I don't mess up my measurements while doing so  but mostly right now, its been a big concentration on the wood work final paint? I'm actually thinking about gloss black with a hunter green waterline for this one. another thing i noticed with KMOTS build, and experienced myself on my last build.. no good way of paint stuff "brass". the parts in the kit are all of a soft cast metal composite. the rudder I have no problem painting the same colour of the anti fowling.. water line paint.. every thing else.. blah.. I wonder if its possible to electroplate the parts to brass? I know copper sulphate and a lantern battery will do it for copper.. but what of brass? in either case, the Parts are all tiny and shipped loose.. if all the metal was on a casting tree, that would be easier. what can you do though? adapt! I probably wont mate the halves until next week. sub wood work is.. mostly done, next is mechanical and electrical thanks for putting up with my rambling. the elliot bay is still drying.. now I gotta get back to work on the dumas ace sloop! or baring that.. any good suppliers of real brass hobby fittings that can be recommended? edit.. forgot to post the pic... |

|

|

Last edited by bgnome; Jun 08, 2010 at 11:32 PM.

Reason: forgot something

|

|

|

|

|

|

|

|

well, work is progressing on the little Guy, as anyone reading Kmots thread might know.. I've been actually out sailing the older one a whole lot because conditions has been so nice for it!

any ways, this thread is more about doing things a little diffrent from the first build and taking more group think advice. mostly I want to illuminate the boat as well I was going to use a LED on a stalk for the rear flag pole for a lamp, but i was out at the hobby town today and they proved to not be completly useless this time! I found this little mast light and it fit perfectly on a little brass tube I had. so this is the rear mast.. its nice to have a scale bit for it, and they have matching bow lights as well and will be picking them up. I just wish it was brass. oh well |

|

|

|

|

|

|

|

|

Dangit!

I got ahead of my self and I paid the price for it. after being saticfied with the rudder servo placement, tested everthing for fluid movement I went ahead and seated the rudder horn with CA glue. I was going to use JB weld.. or even better, just solder the joint.. which was sloppy as hell any ways, but.. I raced. its my own dang fault. what happened was the glue seating the servo was cured enough to do a radio test. the problem was is that the CA glue wicked down into the rudders stuffing tube and bound it up. the servo movement sheared the rudder shaft where the horn connects to it. so now i have a busted rudder shaft with the square section CA'd inside the horn.. I currently have the horn soaking in some acitone to hopefully release it so I can solder the section back to the shaft and try again but I'm not holding out much hope. I really, really shouldve solderd the connection Astro? paying attention.. put a bead of solder on that joint! so.. if I cant get the horn to release its little captive, I'm going to contact Midwest and see if they can send me a new assembly, baring that... I need to construct a custom rudder assembly. and that's actually alright.. I have a good idea of how I will do it, but in either case.. i think construction is shut down for at least a week

|

|

|

|

|

|

|

|

|

yes..

I have some 1/8 brass tubing and it fits perfectly snug in the stock rudder stuffing tube.. I also have some 1/32 brass shim stock... now....one only needs to slit the tubing perfectly down the center....... NO! I shall cut the brass shim stock a 1/2 inch wider than the final demenision, aneal the sheet, hammer its shape around a 1/8" form, then braze the new rudder to the new brass rudder shaft! AHA! |

|

|

Last edited by bgnome; Jul 20, 2010 at 10:29 PM.

|

|

|

||

|

|

Quote:

This was well tested, I re-painted the hull twice had it shaken up, upside down and every which way re-sanding the hull, silicon held just fine. I saw no reason for JB or CA if you have a snug fit, the piano wire is also bent to help hold it in place too. Gary |

|

|

|

||

|

|

|

|

|

silicon is a good idea as well, and it went through my head as well. just wanted to get to the rest of the build.

the horn has been soaking in the acetone for a couple of hours now and there seems to be no releasing yet. and that's alright.. I think my custom rudder will be nicer any ways.. and it will actually BE brass instead of trying to figure out a way of trying to make it look like brass or just painting it the same color as the anti foul like the other one. but that's for tomorow night.. after I show off the original to some city dignitaries... |

|

|

|

|

|

|

|

|

interesting day!

the Lana Marie had an audience of dignitaries from the City of Richmond's Department of Parks and recreation during an Ice cream social held by the Friends of Bryant Park. Richmond Virginia is now OFFICIALLY RC boat friendly! and the Lana Marie will be plying the waters of the park during the Parks 100 year anniversery party on the 25th of september. with any luck this boat, Huffnung, might be ready. well.. maybe pilimanary sea trials. didn't much care for the pond I was on. the pond was like glass for the most part, but there were spots of noticeable current. current would be fine if it was consistent, but lower young's pond was born of a mill race and the inflow from upper young's pond comes out from under the ornamental overflow damn in odd locations. But Enough about all that.. I have a rudder to fix. the acetone didnt weaken the CA glue enough to release the little bit of metal in order to do a repair, so I made a new rudder using brass tubing and shim stock. first step was to trace out the old rudder form to the brass stock, adjust the trace to accomodate the bend. after cutting out the rudder shape with straight cut aviation snips, I shaped the bend with a small ball peen hammer around a piece of steel 1/8" rod as a form. once the U-bend was formed, 1/8" brass tubing was fine sanded with steel wool, then the rudder was braised with regular solder to the tube. fine files, 180 grit sand paper, and steel wool were then used to fully clean the joint. the 1/8 brass tube did not have enough rigidity, so that tube was stuffed with a 3/32" tube, which was then stuffed with 1/16" wire, all brass. the inner tube was cut shorter than the main shaft and the wire shorter than that. every thing centred, then tinned on either end to secure, then filed and shaped. why didn't I just use a single piece of 1/8" brass rod? the hobby store was closed. and besides, they wouldn't have had it anyway. the useless bastards. for a control horn I retrieved the old control horn, and drilled out the center post to 1/8" now it all lines up and all is well the world, and I think it looks just fine after fine shaping and a quick buff with steel wool. for securing the control horn? I'm going to run out to the LHS and see if they have a 4/40 tap and hex head set screws. and set the screws 90 degrees from each other on the shaft with a final drop of silicone on top to make sure. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Oh I've been thinking of a kitchen rudder since the first one as well. I belive I have all the details worked out in my head. I gotta couple of micro servos in the storage unit, if I had a surface computer radio I might be all on it. The biggest issue I see right now is setting all the linkages and clam shells so when the sticks are at rest, the boat is in... well, nuetral.

But yes, this new design with the rudder servo bay hatch and control horn set screws, I can adress the issue at my liesure. And tom, yeah, it is nice, I think the nitro speed guys might still have an issue though....  Can't say it was a hard sale either. There never really was a problem, this just now makes the not being a problem thing city policy. The fun part now is that we want to have a official float at the park on the centenial bash sept. 25 and promoting that effort, that's where the marketing is really going to come into play. I have some media cards I can play through Santa Peege. If there's abig national model boating compition event, I need to know about it because we have a great location for something like that in byrd park. |

|

|

|

|

|

|

|

|

Did I mention that I have a love hate relationship with my LHS?

I love to hate them, but they are there and they more often than not have the stuff I'm looking for, or a close approximation of what I need. instead of 4/40 set screws I had to settle for 2-56 hex head screws as it was the only thing they had close to what I needed. and I had to find it for them. they recently reorganised the store, and it would appear when they moved all the great planes and dubro hardware, they just yanked it off one wall, and put it on another wall indiscriminately.. I mean literally, everything is everywhere and when I found what I could use while the guy was rummaging around the car stuff I said, "its cool.. I think I can use this" dude looks at the stuff "that wasn't in the computer?" GAH! alright.. enough of my ranting..lets build a boat as it turns out, the rudder post was about 1/2" too high for the hatch.. a quick shot with a cut off disk in the dremel and a quick re-flow later.. good to go. hook to the servo up to a radio to check for Zero. WAY OFF! re adjust the horns, locked down.. all is well with the world. well.. lookie there... the control stuff is done... it is time now to lock the deck to the hull. the plastic cement I was counting on is not suitable.. this stuff is more for plastic model kits.. its fine for small pieces of this ABS but the two place set time is far too short for this big of a joint... Damn... BUT WAIT!!! I've had to do a great deal of plumbing in the past few years... time to check out the reserves of assorted Home maintenance crap in the garage.. and there it was.. daty all purpose cement.. suitable for PVC, ABS, and CPVC grab a some test pieces of scrap hull material and adhere them.. fist raw, then with some purple PVC primer.. both joints are good, nothing dissolved, perfectly set within 15 minutes. still.. work time is short, so work fast! no primer.. slather the junk on, slap the deck to the hull..work in sections, get lock, wait fifteen minutes, then wrap with #64 rubber bands to cure for two hours. remember when when you were a kid and you lost all track of time doping up model aeroplane wings in your room? when your mother knocked on the door wondering what you were up to in there? "nothing ma, just working on my planes!" yeah... well ventilated area... dope is an appropriate name. TIME MARCHES ON! the cement has cured hard enough to begin breaking the tabs off... everything looks pretty good, have to spot glue in a few areas, but the hull is good and true. all that's left now is to leave the dang thing alone to fully ripen, then begins the task of sanding to shape |

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Discussion | Elliot Bay Steam launch | Kmot | Steam Boats | 865 | Sep 14, 2013 11:45 PM |

| A'ight, who has an Elliot Bay Steam Launch? | Kmot | Scale Boats | 18 | May 03, 2009 05:52 PM | |

| Sold | Midwest Elliot Bay Steam Launch and Engine NIB | dds7197 | Boats (FS/W) | 6 | Oct 02, 2005 01:45 PM |

| Midwest Elliot Bay Steam Launch, no time to build | dds7197 | Scale Boats | 0 | Sep 28, 2005 06:49 PM | |

| Alert | Midwest Elliot Bay Steam Launch, no time to build | dds7197 | Dock Talk | 0 | Sep 25, 2005 11:53 PM |