|

|

|

|

Thread OP

|

Build Log

Another DIY Scratchbuild

Let me start by saying that I have been building and flying RC planes for over 25 years. The proliferation and popularity of helis is what tweaked my interest in quads. I began by reading and absorbing everything I could. Slowly I began to conceptualize the quad I wanted to build.

These general parameters led me to decide on a 55 size quad weighing around 1200 grams. Forget cameras, FPV, gimbals, and all that other stuff for now. Let's just build a quad that will survive this flying season and that I can have some fun with in between wringing out one of my 50 cc gassers. So I fired up my AutoCad program and sketched up what my quad was going to look like. Attached is a .pdf file showing the plan and elevation of my proposed build. |

|

|

|

|

|

|

|

|

|

|

If you want a cheap quad to thrash around I think you might be going in the wrong direction. You can build a 400mm Hquad frame for about 4 bucks in 1/2" wood dowels and 1/8 birch ply. Run some 8 dollar Emax 2822s with cheap gemfan 8x4.5 props. This would allow you to use a 2200mah 3s for 8-9 minutes of tooling around. SimonK F30A escs and a Flip multiwii FC or a KKv2 if you want onboard programming without a bluetooth module.

The Hquad frames are hella tough and very rigid and dirt cheap. |

|

|

|

|

|

|

|

|

I can recommend using 4x 1300kv 24g "bluewonder" on a 330 quad. That's one of my setups and I can fly for over 20 minutes with great tracking and handling, on a 2200mah pack that is. I think that my AUW is around 470g. There's tons of power for acro aswell.

Edit: Im using 10 amp ESCs and a HK MWC board. |

|

|

|

|

|

||

|

|

Quote:

|

|

|

|

||

|

|

||

|

Thread OP

|

Quote:

This thread will take you through my thought process in the design and build stage, highlighting some of the things that I would do differently. Hopefully it will be of some use to others who are contemplating a plunge into quads. Al |

|

|

|

||

|

|

||

|

|

Quote:

|

|

|

|

||

|

|

|

|

Thread OP

|

Another DIY Scratchbuild

Frame Construction

My frame is constructed from materials purchased at Lowes for about $35. The arms are 3/4" aluminum square tube (.055" wall thickness) and .088" thick Lexan. The aluminum arms are sandwiched between the Lexan plates using 10-32 bolts and locknuts. In order to make the frame lighter I drilled and reamed a series of .40" holes on 1" centers in the aluminum arms. My first choice would have been carbon fiber for the frame but I didn't want to spend that kind of money on this project. So I'll just accept the additional weight penalty. The total weight of the frame assembly turned out to be 437 grams or about 130 grams more than I was expecting. Let's see what the all up weight will look like. Using the actual weight of the frame and posted weights of components from Hobby King I came up with the following table: Frame: 437 grams Motors (4): 288 " Battery (3300 mAh): 255 " ESC (25 amp) x 4: 88 " KK 2.0 Controller: 38 " Receiver: 39 " Wiring, etc. (est.) 55 " Props (11 x 4.7) 44 " Landing Gear 80 " Total 1324 grams I may be able to shave off a few grams by using whiffle balls for landing gear. We'll cross that bridge when we get to it. Motor selection is the next step. |

|

|

|

|

|

|

|

Thread OP

|

Another DIY Scratchbuild

Motor Selection

Motor selection was more of a trial and error process. Cost and availability were considerations as well as quality and reliability. I chose to use one of the more popular Turnigy motors since there seemed to be more data available at the time I made my selection. I used the e-Calc calculator for Multicopter to aid in my evaluation. http://www.ecalc.ch/xcoptercalc_e.htm The parameters I set up were a 3S LiPo 3300mAh-35/50C, a 20 amp ESC, and an APC SloFly 11 x 4x7 prop. As stated previously, I was aiming for an all up weight of 1200 grams so that is what I plugged into the calculator. After evaluating a number of different motors in the calculator I finally settled on the Turnigy 2217-20T (860kv). https://www.hobbyking.com/hobbyking/s...Outrunner.html Current never exceeds 20 amps, will hover at 47% throttle and give me 4 to 12 minutes of flight time. In addition I have a 3.67 to 1 ratio of hover power to max power. See first attachment. Here is some additional performance data. The first set is from Hobby King and the second set is from an independent user. Both sets of data compare favorably with the calculator. Hobby King Data Voltage\ Current\ Prop \Thrust 11.1V\ 12.3A\ 10x6 \800g 11.1V \16.3A\ 10x7 \970g 11.1V\ 17.9A\ 11x4.7 \1040g Independent Data Prop\Watts\RPM\Amps\Thrust APC slo 11x4.7\210\6600\19.5\1156g APC slo 11X3.8\175\7200\15\1047g APC thin E 11X5.5\175\7500\15\1047g But wait, my quad is going to come in at around 1324 grams. How will this impact the performance of the motors? I plugged 1324 grams into the calculator and the result was quite favorable. Current draw is hardly affected, flight time is between 4 and 11 minutes, and it will hover at 53% throttle. It maintains a 3.65 ratio of max power to hover power. See second attachment. The one thing I don't like about these motors is the mounting and prop adapter arrangement. These are extra parts and could contribute to excess vibration if out of balance. Finally, here is a price comparison between some equivalent motors: Turnigy 2217-20T (860kv) - $15.98 SunnySky 2216 kv 880 - $22.50 http://epbuddy.com/index.php?main_page=index&cPath=31 Park 450, 890 kv - $47.99 http://www.horizonhobby.com/products...890kv-EFLM1400 |

|

|

|

|

|

|

|

|

Sunnysky motors are worth the extra price. They are extremely well balanced and come with quality bearings. They also come from the US if ordering from epbuddy so shipping is much faster/cheaper.

It difficult to read your design goals and then look at the materials and design you choose. To me they do not match well. |

|

|

|

|

|

||

|

Thread OP

|

Quote:

|

|

|

|

||

|

|

|

|

Thread OP

|

Another DIY Scratchbuild

Soldering Connectors

In my previous post I mentioned some of the negatives associated with the Turnigy 2217-20 860kv Brushless Motor. One of the negatives that I did not mention was the fact that you had to solder on the 3.5 mm bullet connectors. However they did supply a set of male and female bullet connectors with the motors as well as some shrink tubing. For this project I also chose to use the Turnigy Plush 25 amp speed controller. https://www.hobbyking.com/hobbyking/s...ontroller.html Well guess what Ė these ESCís also came without bullet connectors. So the next step in the process was to get the 3.5 mm bullet connectors soldered on to the motors and ESCís. Here are some thoughts on making good solder joints. First, make sure you have a good 100 watt soldering iron. Those pencil type 25 and 40 watt irons are good for printed circuit boards but wonít do much good making heavy duty connections. I am still using a 60 year old soldering iron that was given to me when I was 15 years old! Use 60/40 .032Ē rosin core solder. Tin (coat with solder) the soldering tip first. When the iron gets hot clean the tip with a smooth file or sandpaper and apply solder to the tip so it is nice and shiny. Wipe off excess solder. The tip will oxidize quickly so before making a solder joint it is a good practice to wipe the tip on a damp sponge. A heavily oxidized tip will impede heat transfer and result in a cold solder joint. The ends of the motor wires were already stripped back so I just tinned them with some solder that I was going to use to make the joint. The motor leads get male bullet connectors. I ran some solder into the end of the bullet connector until I filled the cup. A third hand soldering helper is indispensable for this type of work. Then I lined up one of the motor leads with the connector, heated the connector until the solder melted, then plunged the wire end into the connector. You need to hold the heat on the connector long enough for the solder on the wire to melt and fuse with the solder in the connector. I repeated this for the other two wires then slipped on some heat shrink tubing. I used a MonoKote heat gun to shrink the tubing on the connector. I repeated the process for the ESCís by soldering female bullet connectors to the motor side. The battery side gets 3.5 mm male connectors. Unfortunately the ESCís donít come with loose bullet connectors so you have to pick up some extras for these situations. https://www.hobbyking.com/hobbyking/s...IRS_20PC_.html You may have noticed that I am using a power distribution board to deliver power to the ESCís. This board is fitted with 3.5 mm female connectors so that saves quite a bit of soldering in order to make a power distribution harness. It saves a bit of weight as well because #10AWG wire is quite heavy. https://www.hobbyking.com/hobbyking/s...ion_Board.html I had one more soldering job to do in order to finish up this part of the project. The battery connection on the power distribution board uses a XT-60 connector. This connector is rated for 60 continuous amps. The batteries I purchased (3300 mAh nano-tech 3S Lipo Pack) come with 4mm female bullet connectors. My task then was to replace the bullet connectors on the battery with a female XT-60 connector. This is where the heavy duty iron really comes into play because you have to solder #14 AWG wires to the connector terminals. You have to be careful here to avoid shorting the ends of the connectors when performing this operation. Again a third hand soldering aid and a high wattage iron are indispensable. The final picture shows all the motors, ESCís and battery with all connectors soldered on. |

|

|

|

|

|

|

|

Thread OP

|

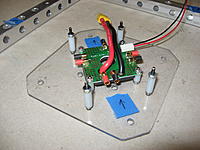

Assembly

Well itís time to start putting all this together. Letís start from the center and work our way out. The bottom Lexan plate has the power distribution board bolted on with 4-40 hardware. Then a battery tray is bolted on to the bottom plate using nylon spacers and 4-40 hardware. The battery is secured to the tray using a Velcro strap. The top plate has a Lexan electronics board mounted it to it using 4-40 nylon hardware and rubber grommets to limit vibration transfer to the KK2 board. The KK2 is attached to this plate in a similar manner. I soldered a pair of leads and a BEC connector to the KK2 board for the low voltage alarm. Best to use a 25 watt iron for this task. The motors are mounted to the ends of the arms using 4-40 socket head cap screws and locking nuts. The cap screws are threaded through a 1/16Ē aluminum retaining plate that I made just for this purpose. |

|

|

|

|

|

|

|

Thread OP

|

At this point I thought I would weigh the entire assembly including the ESCís (which are not permanently mounted yet. Holy Quad copters Batman! This thing weighs over 1500 grams (48.4 oz.) Thatís roughly 3 lbs. Boy thatís a far cry from my original estimate of 1200 grams!

My question: Is this typical for a 550 size quad? Or is this fellow way overweight? Oh well, nothing to do at this point but to soldier on and see how things turn out. Last night I started to configure my ESCís using the Turnigy Programming Card.https://www.hobbyking.com/hobbyking/s...ming_Card.html Wouldnít you know it, the card s__t the bed after configuring two ESCs. I guess Iíll have to do the other two using the roadrunner method (beep Ė beep). Here are the configuration settings that I used: Brake Setting: Disabled Battery Type: Li-xx Low Voltage Protection: Soft Cut-Off Cut-Off Threshold: High Start-up mode: Soft Timing: High Can the Turnigy Plush ESCís be flashed to improve their performance? Is it really worth doing? Meanwhile, I focused my attention on the KKv2.0 board. I assumed that it would ship with the latest firmware. Well you know what happens when you ASSume. It came with the v1.1 firmware; I want the v 1.4 firmware. So I went ahead and ordered an USBasp adapter. https://www.hobbyking.com/hobbyking/s...occessors.html While I wait for the adapter to show up, Iíll finish configuring the ESCís and get everything wired up. |

|

|

|

|

|

||

|

|

Quote:

If you set the esc with lipo cut off, you will crash. Quads can pull a few amps during climb out. If you are near the end of the pack and try to punch it, the amp draw could cause a voltage sag triggering the cut off. Might only trigger one ESC, but that is all it takes and you quad will smash into the dirt. Proper setting for esc is no cut off. Then be sure to have an external voltage alarm, or set a timer. 1500g is pretty porky for 550mm. My 500mm quad with full fpv setup is only 1190g. Difference use light ply and basswood. You are using structural steel and sheet glass  Edit: This thread has a pic of what I think is proper esc settings for a multi-rotor. https://www.rcgroups.com/forums/show....php?t=1384846 |

|

|

|

Last edited by Nick_P; Jan 15, 2013 at 11:01 AM.

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Build Log | Not a DIY Scratchbuild! But a build nonetheless. | AcroFPV | Scratchbuilt Multirotor Drones | 186 | May 16, 2013 09:00 AM |

| Build Log | Another DIY gimbal | recep | Scratchbuilt Multirotor Drones | 0 | Nov 02, 2012 02:34 PM |

| Discussion | DIY saves me another thousand $ | AustinTatious | Life, The Universe, and Politics | 21 | Jun 21, 2012 11:36 AM |

| Discussion | New DIY Scratchbuild products from Altitude Junkies | airbagit13 | Foamies (Scratchbuilt) | 0 | Jun 04, 2012 03:43 PM |

| Discussion | Another DIY diveristy controller | Slaphappysamy | FPV Talk | 5 | Mar 02, 2012 09:57 AM |