|

|

||

|

Thread OP

|

Quote:

most of the before listed suppliers of OPS marine engines will also help you to obtain the required "aero" engine parts for converting your marine engine to aero-speed-application. As we know the marine and aero engines do share many parts. However, you may also try to purchase a NIB actual OPS .45 FAN engine. It should be equipped with the new drum rotor valve and the actual higher-timed 3+2 ports piston/sleeve assembly #4376 and the actual heavy duty ERGAL/DURAL-connecting rod. This current OPS .45 engine is more powerful than the OS .46 VX-DF for instance.   To enable a quick order it is advisable to provide the numbers of the OPS aero-specific spare parts. So here's the parts list for the conversion from the #8710 OPS .45 speed SPP RCB marine engine (slightly lower-timed disc rotor intake valve engine, it was replaced by #8711)to the OPS .45 speed SPP FAN aero engine

In case your goal is all-out straight line speed for competition purposes the conversion to the OPS .45 speed SPP “VAE” aero engine (it will look like the OPS .40 speed SPP PYL, see pics below) requires:

|

|

|

|

Last edited by I-Love-Jets; Jul 26, 2009 at 07:15 AM.

|

|

|

|

|

|

||

|

Thread OP

|

Quote:

http://www.mantuamodels.co.uk/pagevi...GINES&cust=207 http://www.mantuamodel.com/index.php...elli&Itemid=92 Mantuamodel is the main European distributor for the brand OPS: Mantua Model Via Statale sud 2/3 46048 Santa Lucia di Roverbella Mantova Italy P.I. 00048900203 mantua@mantuamodel.com info@mantuamodelhelp.com http://www.mantuamodelshop.com/contact_us.php Tel. (+39) 0376-270287 from Monday to Friday: 09-12 - 14-17 Tel. (+39) 0376-697087 Tel. (+39) 0376-697088 Fax (+39) 0376-697272 Mantua Model Uk Ltd 179 Dedworth Road Windsor Berkshire SL4 4JN info@mantuamodel.co.uk Tel: (+44) 01753-856321 FAX: (+44) 01753-857444 Postage charge will be up to £10 = £3.50, up to £20 = £5.00, up to £50 = £8.00 Over £50 Postage is FREE, within Great Britain. Deliveries Abroad: Please e-mail us with your order and we will quote you including postage. Make sure you give your full address so we can price the postage correctly. Postage will be charged at cost. If outside the EU we will deduct UK Tax of 15%. OPS headquarters Italy: Rc Power S.R.L. Via Giacomo Matteotti,128 20041 Agrate Brianza Tel.: (+39) 0396-890424 FAX: (+39) 0396-890428 As for shipping abroad, MANTUAMODEL UK or MANTUAMODEL ITALY for instance have shipped many times to the US in the past. GUNDERT and HYDROMARINE do also ship internationally (usually without national VAT outside the EU). |

|

|

|

||

|

|

|

|

|

Thanks

|

|

|

|

|

|

|

|

Thread OP

|

And now comes the parts list for the conversion

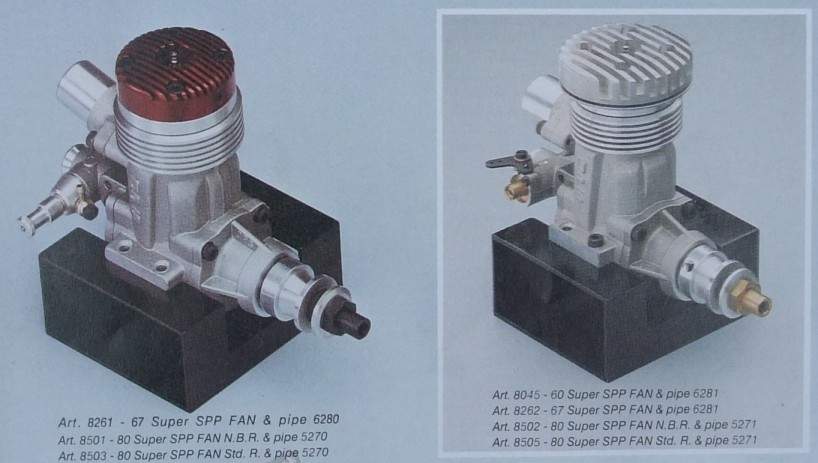

from the OPS .65 speed SPP RCB (#8270) marine (slightly lower-timed disc rotor intake valve engine, it was replaced by #8271)to the OPS .65 & .67 super SPP FAN aero engine:

In case your goal is all-out straight line speed for competition purposes the conversion to the OPS .65 & .67 super SPP “VAE” aero engine (it will look similar to the below shown goldhead OPS .60 super SPP VAE) requires:

|

|

|

|

|

|

|

|

Thread OP

|

So let's now do a conversion of an OPS .65 speed SPP RCB (#8270) marine to create the OPS .65 SPP FAN aero engine.

This is our slightly used powerful 5-ports goldhead OPS .65 marine engine we just bought from a buddy:  After disassembling the engine we are carefully cutting a slot into the aluminium water cooling ring of the cylinder housing. The fine hacksaw blade of our bow saw must not touch the engine case at the sealing gasket locations!  Then just before the aluminium cooling ring has been sawn through, we are spreading the slot using a screwdriver. The cooling ring now can be pulled off the engine easily.    We thoroughly clean the entire engine housing outside and inside with warm soap water – no aluminium swarf will be left. Finally we are taking the aero-specific spare parts (prop driver, exhaust header), we're swapping the front and rear end and we're reassembling our former marine engine. So this is our “new” OPS .65 speed aero engine ready to go for 210 or more mph (depending on airframe aerodynamics and and speed propeller choice).    |

|

|

Last edited by I-Love-Jets; Jun 20, 2009 at 08:17 AM.

|

|

|

|

|

Thread OP

|

And now comes the parts list for the conversion from the 3+2+2 ports red or bluehead OPS .80 speed SPP RCB (#85000) marine = disc valve + bronze bushed conrod engine to the OPS .80 super SPP FAN aero engine: (#85010) = disc rotor intake valve + needle bearing conrod engine  parts needed:

In case your goal is all-out straight line speed for competition purposes the conversion to the OPS .80 super SPP “VAE” aero engine requires:

|

|

|

|

|

|

|

|

Thread OP

|

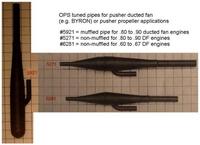

Below shown is a special pusher configurated OPS .67 Super SPP FAN engine.

This high performance engine will be mounted in a pusher prop driven speed delta in future. The special thing here is that this OPS engine is set up to rotate reversely ( = clockwise)!  Because of that the standard tractor-type carbon fiber props can still be applied for the pusher delta project.  That's a great advantage due to the lack of suitable carbon fiber pusher props... That's a great advantage due to the lack of suitable carbon fiber pusher props...The following links do explain the simple procedure to make all disk rotor valve OPS engines run reversely: https://www.rcgroups.com/forums/show...7&postcount=21 http://www.rcuniverse.com/forum/m_79...tm.htm#7990063       The large (60 mm diameter) OPS .65/.67/.80 heat sink cylinder air cooling head #6955 generally can be combined with:

The above shown muffled pusher-style tuned pipe was made by BYRON and isn't available any longer NIB. It is suitable for .60 to .67 sized DF engines. At that time BYRON also offered a similarly looking .90 tuned pipe (for the OS .91 VR-DF “large head” in particular). It is not easy to find pusher-type tuned pipes today.  But there are still several options: But there are still several options:OPS:

MERKER (index- ”F” muffled pusher tuned pipes): http://www.merker-modellbau.de/impeller.htm

Weston UK (mini pusher tuned pipes): http://www.westonuk.co.uk/new_website_189.htm

|

|

|

Last edited by I-Love-Jets; Aug 15, 2009 at 08:47 PM.

Reason: dead link

|

|

|

|

|

Thread OP

|

There are often private sale advertisements and auctions of OPS .67 (11 cc) and .80 (13 cc) marine engines. But the sellers sometimes do mix up the .67 and .80 engines due to their very similar appearance.

For that the following pics show the most significant differences of both engine cases. Especially the widened exhaust flange of the .80 engine helps us to identify the offered engine at first sight.

|

|

|

|

|

|

|

|

|

Thanks "I Love Jets" for the information.The amazing part is these engines are still at the top of class today yet most are designed 20 years ago!

Danny |

|

|

|

|

|

|||

|

Thread OP

|

Quote:

So what .15 OPS engine do you have? - There are several FISE ( "SLA" ) and FIRE ( "SPA" ) versions, differently timed and with different carb bore diameter. Please tell us

Quote:

A 6x5.5” speed prop sounds OK in terms of prop load for your engine (piped!) and in combination with this small delta airframe. These are the different versions of the 2.5 cc OPS aero engines: FIRE configuration

FISE configuration

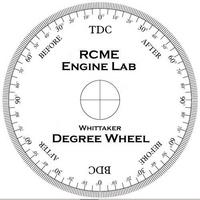

So your OPS .15 R/C FISE is #8170 (because of the R/C carb). As for the crankshaft bore diameter of your engine I assume it has 8 mm. Sadly a 6 mm carb bore is too restrictive for 23000 or more rpm. For that a carb bore of 7 to 7.5 mm is highly recommended in your case. So you should swap your Perry carb... To find the right tuned pipe length you first need to measure the exhaust timing using a degree wheel (glued to stiff cardboard for instance). Finally some pics of the hottest .15 sized OPS engine, the 2.5 Speed SPA VAE (to be used with a twin-cone pipe only such like the MACS #1110): |

||

|

|

Last edited by I-Love-Jets; Jul 14, 2009 at 02:00 PM.

Reason: adding a link

|

||

|

|

||

|

|

Quote:

Where does this engine make its best power as is, in other words what rpm do you think I should target; 23,000 as OPS lists in the ratings, or..? Would the #1377 P/L assembly be of benefit as a hop-up for this engine? Thanks for all the cool info. MJD |

|

|

|

||

|

|

|||

|

Thread OP

|

Quote:

For that create a test prop to be used for static test runs only (simulating unloaded flight rpm):

Quote:

In contrast the #8150 VAE engine features the large-bore crankshaft (#1231) with a 9 mm diameter passage. The VAE also comes with one of the mentioned high-timed liners and the big-bore speed venturi #1261 instead of the standard venturi carb # 3260 of the other non-R/C 2.5 cc FIRE and FISE engines. So the very high rpm numbers the VAE .15 engine is capable of (well in excess of 30.000  ) is also the result of considerably improved mixture flow. Therefore it wouldn't be promising to put the high-timed liner of the VAE into one of the other (in this case too restrictive) 2.5 cc OPS engines... ) is also the result of considerably improved mixture flow. Therefore it wouldn't be promising to put the high-timed liner of the VAE into one of the other (in this case too restrictive) 2.5 cc OPS engines...

|

||

|

|

|||

|

|

||

|

|

Quote:

It looks really cool with the little 1110 pipe. I'm just fitting it to my test stand, trying to hold the pipe better after the West header incident. Thx MJD |

|

|

|

||

|

|

|

|

|

I ran the .15 this afternoon! Not able to find my tach.. so limited it to a couple of short full bore runs after getting the carb dialed in. This is my first Perry carbed engine and it was dead easy to set up. With the high end set to the rich limit of 2-cycling, throttle response was lightning-quick with not a hiccup. I'm liking this engine already..

Used the Graupner 6x5.5 prop trimmed down to just under 5.5" - it looks ridiculously small on front of this somewhat stocky .15 (the internals look like it could run 35k all day..). Warmed up the head (it's freaking tight cold), pulled it through to get some fuel in, and a quick tap with the starter and it was running beautifully on a fast "idle". A few throttle-ups and high speed needle tweaks, and it was up and wailing on the pipe in a rich two-stroke and sounding very happy. 2nd run I refueled, warmed the head again, and flipped the prop once - instant start. Not bad for a reasonably hot .15 with about one minute run time - it sure behaves like an OPS. Still real tight cold. Looking forward to finding my tach and dialing in the pipe, it's at 23cm now and from the behaviour can likely stand to be shortened. MJD |

|

|

|

|

|

|

|

Thread OP

|

I just made a list of commercially available nitro powered composite speed planes that are faster than 150 mph and that can be powered by OPS engines too. Included are many pictures and recommendations for high performance engines, tuned pipes and suitable propellers. Maybe you haven't seen some of them yet, maybe you want to add more speed planes to the collection... |

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Question | PB carburater on a OPS engine | coaxial-gyro | Engines | 0 | Dec 16, 2005 05:13 PM |

| FS: Prather 31" deep vee 3.5 OPS Engine | kd1942 | Boats (FS/W) | 0 | Aug 27, 2004 01:29 AM | |