|

|

|

|

|

Build Log

257" B-36D Scratch Build 6 a turning and 4 a burning

Well,

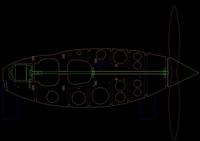

This is the start of my thread on my B-36D project. I started the design 8 years ago with the intent of it be 256" with 6 gas engines, but after doing all the calcs I realized that the plane would weigh over 110 pounds because I would need 45 pounds of ballast to off-set the engines weight at the trialing edge of the wing. Now with electric motors I can build a 257" B-36D and hit about 51 pounds. I have drawn the entire plane in both 3D max, and AutoCAD so I can scale the drawings to any size I need. The plane will have 6 AXI 4130/20 Motors turning Zinger 3 blade 20" props, in testing I get about 5 minutes at full power and 12 at 65% cruise power. I have just got all of my plans printed out on my plotter to start cutting wood. The retracts are going to be Century Jet Models, Inc. and be Scale b-36 gears. I have been using Ecalc and it looks to be spot on with what I am seeing in testing. Will try to update weekly or better. Thanks, DAG |

|

|

Last edited by dag214; Aug 28, 2009 at 09:01 AM.

|

|

|

|

|

|

|

|

I'm here Dag, !!!!

This is going to be awsome !!!! Seeya, Tim |

|

|

|

|

|

|

|

|

Subscribed!

You are crazy DAG!

|

|

|

|

|

|

||

|

|

Quote:

I have ordered the plywood for aircraft spruce and will start cutting next week. Thanks, DAG |

|

|

|

||

|

|

|

|

|

Here I am too!!!

Anxious to see this project flyin' |

|

|

|

|

|

|

|

|

This may sound crazy, but because I have 99% of all the parts drawn, there will not be much guess work, I plan on having this plane in the air by June 2009, that’s if the boss (my wife) does not catch how much I am spending, batteries and motors are over 2.5k

I will post more of the 3D renderings, what is vrey cool is every part I have drawn gets put into a 3D model then I build it in 3D, if the parts fit in 3D then they will fit when I cut the kit out of wood. This is something very cool to me because I have wanted to build the B-36 for over 30 years, for the last 15 I have been getting drawings and photos, I even have this old control-line kit that was made in Japan (though I have never built it). And here I am now about a week from cutting wood. Rock On! DAG |

|

|

Last edited by dag214; Oct 04, 2008 at 09:14 AM.

|

|

|

|

|

|

Hi Dag, What do you think of Tex's idea ?

That might be a good way to think about doing your motors so you dont have a bunch of nose weight. You may have your own ideas already though... I got my power back a week or two ago now !!!! Thank God !!! I dont remember for sure because I am already taking advantage of it !!!! You dont miss it until you dont have it !!! Thanks for asking !! Seeya, Tim |

|

|

|

|

|

||

|

|

Quote:

That is a great idea, I have thought about it on gas power to get the weight at the front of the wing. My wing loading at this point will be about 26oz, that's at 52 pounds so the plane is going to fly great, however if I end up over 55 pounds I will have to look into this. What makes me not like the idea is keeping everything straight so I don't end up with vibration from the shaft and the connections. Do you know of any shafting that would work at about 14” in lenght and turn an 18-12 3 blade prop? Attached is my weight and moment chart. You can see the motors are kind of close to the CG that the true off-set is about 2 pounds of ballast, the rest of the ballast is from the main-L-gear, H-stab and the V-stab. Tim, Glad you are back with us that have power. I will post more 3D rendering of the nose, and hopefully show you some parts cut out by Monday. Thanks all, DAG |

|

|

|

Last edited by dag214; Oct 10, 2008 at 08:07 PM.

|

|

|

|

|

|

|

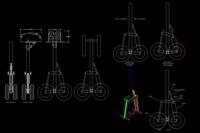

Welllll,

After thinking more about what Tex said about shafting the motors I think it is 110% the way to go. It is funny how you get tunnel vision after designing a plane for a bunch of years. The weight savings will be about 4.5 pounds taking my ballast down a ton. I had a design for shafting G-26 engines and these electrics can't be any harder than those. Attached is the start of the re-design of the nacelles. This site is cool because I get different eyes looking at my designs and builds. Thanks, DAG |

|

|

|

|

|

||

|

|

Quote:

I tested a G-26 with soft mounts and a direct shaft on a prop hub I made myself. It had a 6061 T6 1/2" shaft. The shaft had 3 bearings and was 26" long. The soft mounts allowed the engine not to bind on the bearings. It kept things very light. With this layout, shaft, bearings, and extra bearing bulkheads I am saving 2.65 pounds of ballast. The G-26 did shake a bunch, but I think I will make a test nacelle and see what happens. Thanks, DAG |

|

|

|

||

|

|

|

|

|

Dag, I was having the same thoughts as Tex about gearing the prop drive down some with a belt drive. You could turn the scale props with a smaller motor, and probably save some more weight, overall. The belt drive system should also be easier to keep straight, and vibration free, since your connection to the prop shaft would be via a belt. You could just have a straight shaft running through the nacelle, with a bearing at each end, and probably one near the drive sprocket, if it doesn't end up near the end of the shaft. This kind of a system would give you more flexibility as to the size and type of motors you use. I've also heard that a belt drive system for electrics makes a much more realistic sound than a direct drive motor. I've never heard one, though.

There is a wealth of information available from SDP-SI I sent for their free catalogs, and was very pleased with the information and products they contain. Here's a link to their website: http://www.sdp-si.com/ What a magnificant project you have taken on! I remember as a kid, just after WW II, seeing B-36s flying over our house, out in the hills in western Oregon. Sometimes there were as many as six in a formation. The windows in the house would actually start vibrating before you could hear the engines in the house. The flights would usually go over quite low above the hills, so the noise was amazing. Best of luck with this project, I'll be watching! AmpAce |

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Good B-36 site (drawing with cross sections, too!) | Thomas B | Scale Kit/Scratch Built | 26 | Oct 11, 2011 09:14 PM | |

| Discussion | B-36 B-52 | kgmorris | Scale Kit/Scratch Built | 20 | Jan 02, 2009 07:27 AM |

| b-36 | dorysch1 | Scale Kit/Scratch Built | 32 | Feb 01, 2004 09:33 PM | |

| Questions about my wally B-36...I'm new to foam. | Boba_Fett | Foamies (Kits) | 8 | Jun 11, 2002 03:36 PM | |

| B 36 | Trobber | Parkflyers | 3 | Dec 30, 2001 01:33 PM | |