|

|

|

|

|

|

|

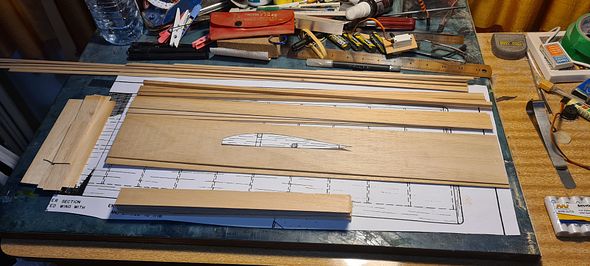

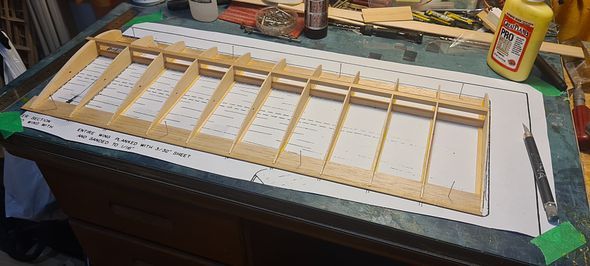

Gene, I've been building RC aircraft since 1973, there are a lot of different ways to build a wing. I worked out to cover the Coachman's wings as per the plans would have cost at least $28.40 AU and that is for just four sheets of 3/32" x 4" x 48" that's $20.88 US. Why spend all that money when all you have to do is move the lower spar forward and use cap strips, so far the only wood I had to buy for this build was 2 sheets of 1/8" for the fuse sides and a sheet of 3/16" for the tailplane, all the rest came out of my scrap box and sheets I've had for over 10 years.

The construction I'm using on the Coachman wing is the same as the wings on my Quiet Advancer 2M glider, (but with cap strips), that glider was built in1985 and still doing well in competition today. Experience comes over time, I know there are purist's out there would say it's not original, but we are aeromodellers, we build from kits, plans and design our own, we see changers that can be made to an aircraft's construction that work, I like to do that. I'm not trying to preach here, just passing on what I do, if it helps others, great. I learn new things every day from other builders, you showed me something new I haven't seen before with your landing gear axils I may use in the future. That's what these forums are all about. I still think I may be going overboard with this log, there are over 50 photos so far with explanations of what I'm doing in the build  , nobody has complained so far , nobody has complained so far . .

|

|

|

|

|

|

||

|

|

Quote:

It's all part of aeromodelling. Dave |

|

|

|

||

|

|

|

|

|

Thanks guys. I was well aware of the d tube wing and cap strips,( i have built my share of them) but could have saved some weight on my Coachman when building the wing.I just never thought about doing it. Thats why i like these build threads. There are many ways to do things....Gene

|

|

|

|

|

|

|

|

|

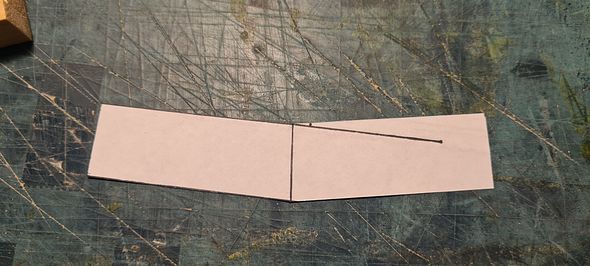

In my other build, "Playmate" (it will be finished after the Coachman's finished) I've made a small change on the wings as well, I added false ribs on the leading edge to cut down on the covering sag on the fully open wing construction. You can do anything, you are only limited by your imagination.

|

|

|

|

|

|

|

|

|

I recall looking at the plan for the RC when it first showed up in RCM. And I thought at the time that the use of the fully sheeted wing was quite excessive. Especially on such a compact size model. So your conversion to a D tube with capstrips option is almost certainly something I'd have done as well. And in fact given how thick the wing is even with the conversion to D tube with cap strips I would likely have opted for 1/16 instead of 3/32 as well. And to make up for the very slight reduction in overall strength I'd have selected my more medium grade sheet stock. It's just not that big of a model. Yet Don Dewey chose to use fairly big model material sizes throughout the design. I'm thinking that he stocked a lot of lighter Contest grade wood in his shop....

|

|

|

|

|

|

|

|

|

Sorry Bruce, I forgot to mention I used 1/16" for the ribs, caps and D-box sheet. I built larger models that only used 1/16" balsa for this type of construction.

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Build Log | VOK 2021 Royal Coachman build. | X30PILOT | Vintage & Old-Timer Designs | 44 | Jul 12, 2022 09:15 PM |

| Discussion | Second half 2021 Build - ABAK | BMatthews | Vintage & Old-Timer Designs | 64 | Feb 04, 2022 08:25 PM |

| Discussion | Scratch building the Royal Coachman | gene6029 | Balsa Builders | 103 | Aug 05, 2021 11:23 PM |

| Help! | Marutaka/Royal.60 Oscar build plans | bob48 | The Builders Workshop | 1 | Jan 14, 2018 09:13 AM |

| Discussion | Royal Coachman | starcad | Vintage & Old-Timer Designs | 76 | Aug 31, 2012 02:44 PM |