| Thread Tools |

| This thread is privately moderated by landru, who may elect to delete unwanted replies. |

|

|

|

|

|

Discussion

Art Hobby Agena ES build pics

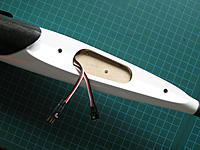

Modified from V-tail to X-tail with flying stab and two piece wing.

ImagesView all Images in thread

|

|

|

Last edited by landru; Jun 02, 2019 at 04:21 PM.

|

|

|

|

|

|

|

|

feedback on 2-piece wing

Thanks for posting these pictures, I am thinking of getting a Skua and the 1-piece 1.5m wing was slightly off-putting. How has it performed and do you still think it was worth the effort? As my first such build, I doubt I can do it to the same standard as yours.

|

|

|

|

|

|

|

|

|

There have been no issues whatever with the two-piece wing. It's still going strong after about 90 flying hours. I'm thinking of using the same technique on an Odyssey -- with bigger wing-joiners, of course.

Was it worth the effort for the Agena? Given that I've never actually dissembled the wing, I'd say it wasn't. That's right. Not once have I taken the wing apart. In fact, I hardly ever remove the wing from the fuselage.  If you're a new builder, the two-piece mod might be a significant challenge. It's not rocket surgery, of course, but a goodly amount of precision is required. The risks are wing halves that may not line up, joiners that bind, and so on. For a 1.5m glider, especially for your first such build, my recommendation would be the standard one-piece construction. Hope this helps. Fire away if you have other questions.  Best, Andrew |

|

|

Last edited by landru; Jul 09, 2021 at 02:52 PM.

|

|

|

|

|

|

Thanks for the advice, that sounds very sensible. I guess it depends on your circumstances as I often hike out to slopes and my Alula is very convenient for that (disassembled in my backpack). However a few hundred grams shouldn't be too difficult to carry, even if it is long. If I change my mind, I could always buy a second wing, although a new model is more likely.

|

|

|

|

|

|

|

|

|

With AH wings I am assuming the load is carried by the wooden skin and the foam is largely a spacer. Therefore the joiner rods can be quite short and only need to transfer the bending moment into the wooden bulkheads? ie. I could build the bulkhead-rod assembly first and if it is not good enough, revert back to one-piece wing design.

|

|

|

|

|

|

|

|

|

Yes, you could definitely glue up a two-piece wing into a one-piece.

And yes, the AH wing construction type is stressed skin. But keep in mind that the foam in the wing core is compressible, and it's what resists the bending forces on the joiner tubes and transfers them to the skin.* Plus, those forces act at right angles to the skin, rather than in parallel (as with glued and FG-reinforced centre joint). For those reasons, I made the main joiner as long as possible. Even then, before flying the Agena, I was concerned that the joiners might distort the adjacent skin, crack it, or perhaps even break though it. Or that the centre joint might be floppy. Thankfully, none of those happened. By comparison, I do see some very light cracking in the skin of my 2m AH Sky wing above the servo pockets and above and below a CF spar that I embedded in the foam before gluing the centre joint. Mind you, I've flown the Sky considerably longer than the Agena (225 hours), more aggressively, and once or twice in light drizzle. For those reasons, the cause of the cracking is up for debate. This winter, I'll sand and refinish the wing. And I'll go with a slightly heavier application of finish this time. Last time, I went very light. If you go with a two-piece design, I'd recommend that you draw up full scale longitudinal sections of the wing where the joiner tubes are located. It'll show how much room above and below the joiner you have to work with according to the dihedral you choose. If it's of any help, I can probably find my drawings from the Agena and post them here. Just let me know.  *Note: This is true for the outboard ends of the joiner which simply 'float' in the foam. If you add ply roots at the inboard ends as I did, those roots will provide a very firm anchor. |

|

|

Last edited by landru; Jul 09, 2021 at 06:32 PM.

|

|

|

|

|

|

With the Alula there is a carbon spar that is only connected to wing joiner tubes by a few cm of foam, and this soon starts to disintegrate. For this reason I was thinking of a design which would avoid loading the foam at all and be as close to the original design as possible: the force would be transmitted only through the wooden bulkhead and I would also add some reinforcing glass internally joining it to the skin in a similar way as the two halves are normally joined. ie. the opposite approach to a long joiner. I couldn't say which would be better without some testing or FEA. Perhaps a good reason for me to stick with the standard one piece design?

It is interesting that you see cracking near the servo pockets. Maybe it would be better to avoid joining the servo box to the upper skin to give a more uniform wing bending stiffness? Is there an expected life in flying hours of these models? How do the AH designs compare to other construction types? |

|

|

|

|

|

|

|

|

Hi again yyagi. Apologies for this very tardy reply.

I'd like to understand better your idea for a wooden bulkhead. I suspect it may be the same as my using a ply root rib on each wing panel to carry the load of the joiner tube. If so, I can say the technique works great. Looking at the condition of my Sky 2m wing, it's further outboard where any compression and flexing might occur. The cracking of the veneer above the flap servo pockets may be due to my omitting the boxing of the servo bay. Instead, I laid in an additional hard balsa floor. Perhaps that wasn't enough. I also suspect the finish, or perhaps its thickness. I used water-based polyurethane on the Agena. It still looks brand new. Mind you, I found out later that AH recommends against WBPU. Aparently it has caused de-lamination of the veneer from the foam in some cases. Judging from my Agena, I'd expect a well-built and cared-for AH model to last indefinitely. |

|

|

|

|

|

|

|

|

No problem.

My idea is for the wooden bulkhead to connect to the upper and lower skins in place of the other wing half: similar forces would be transferred here in both the 2 or 1-piece construction. The joiner tube would only be a means of transferring tensile load (due to bending of the wing) between the bulkheads, not any further inside the wing. The compressive load on the opposite side of the the join (top or bottom according to loading direction) will be transferred by contact. As an alternative to the joiner tube, I was considering overlapping eyes from each wing half that the wing attachment screws would pass through and so resist tension in the joint (a pair at top and bottom for each screw so 8 eyes). The difficulty would be making this without any lash. Maybe drawings are needed to clarify? However I'm still leaning towards a single piece wing. I am thinking the servo box would provide an alternative load path around the hole in the lower skin. As the upper skin is untouched it doesn't any reinforcement? Great to hear, looking forward to getting one. Hopefully by the time it is built my flying skills will have improved sufficiently... |

|

|

|

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Discussion | Art Hobby Velvia build log. | cityevader | Slope Soaring | 52 | Jun 27, 2018 10:33 PM |

| Build Log | Art Hobby Agena-EV 1.5M | jh2rc97 | Electric Sailplanes | 46 | Sep 30, 2017 06:22 PM |

| Discussion | art hobby agena | txg8gxp | Electric Sailplanes | 2 | Aug 25, 2012 12:33 AM |

| Discussion | Art Hobby HiAspect ES 3.1M | mark_ar | Electric Sailplanes | 42 | Jun 11, 2010 05:49 PM |

| Art Hobby Agena | IMRC | Electric Sailplanes | 3 | Mar 27, 2003 11:43 PM | |