|

|

||

|

|

Quote:

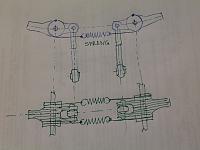

Horst Rabiger have made way more complicated gearboxes using plywood . Plywood is easy to work with espetially when making everithing by hand tools . You still have a lot of room to make it more nerower and respectively light . I will draw a sketch for you . This way you can achieve much beter aerodinamic quality because everithing is inside the fuselage including springs and conrods . Springs are stretched by strings which are pulled by pulleys mounted firmly to spar holders .This way pull force on the springs is more even thru the stroke . By profiling the pulleys ( making them other than round and center coaxial)the spring force can be modulated . |

|

|

|

Last edited by ZTEX; Dec 06, 2018 at 09:46 PM.

|

|

|

|

|

|

|

|

|

Flapping mechanism for full size ornithopter made by Mr Harris for DeLaurier ( University of Toronto engine powered )Ornithopter

|

|

|

Last edited by ZTEX; Dec 07, 2018 at 02:09 PM.

|

|

|

|

|

Thread OP

|

no CF for spars?

Are you suggesting not to use CF for the wing spars? I was planning to do so since this is what many popular models use. If not CF, what material would you suggest? Also I don't have a clear idea how to design the joints where the spar meets the flapping mechanism - the ferrules. Just any aluminum or ABS ferrule? Does the length matter? How should the spar be fixed, with a set screw? I have seen nested ferrules, but I am not sure why people do that. Any recommendations to minimize the risk of spars breaking?

|

|

|

|

|

|

||||

|

|

Quote:

For the high performance sports cars CF Drive Shafts are used but there spetiall method for winding the threads are used and the shaft forks are glued to the CF tube .

The best design for those ferrules is similar to the clevis design but with one more hole for the pivot point . Will make a sketch for you later . https://www.ebay.com/p/2-Brake-Throt...769a2affe03744 The length , longer is better ( usually the spars broke at the point where they come out of the ferrules ) so probably long ABS tapered ferule will be beter ( the flexibility of the material and the taper will help as well for the longevity of the spars ) . If the ferules are made from aluminum then at least you have to round the edge of the ferules holes where the spars come out of the ferules . The best way to conect spars to ferules is the spars to be pressed in to ferules holes and / or to be glued to them. The problem is that such a solutions are more dificult for repairs in case of faluare . Using set screws for fixing spars to ferules isn't good idea as well and because of the reason which I already explained . |

|||

|

|

Last edited by ZTEX; Dec 09, 2018 at 10:58 PM.

|

|||

|

|

|||

|

|

|

||

|

|

|||

|

|

|||

|

|

Hi,

from the university Delf in the Netherlands , a very agile insect inspirated flapper.

Happy Amps Christian |

||

|

|

|||

|

|

||

|

|

Quote:

Flapping mechanisms are from 20 $ I bird pigeon from eBay or Amazon. The ingenious thing is the way this enthomopter is controlled . Independent flapping frequencies on left / right wings pairs , variable anhedral/dihedral and differential variable angle of attack on both wings . |

|

|

|

Last edited by ZTEX; Dec 17, 2018 at 05:24 PM.

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Discussion | Sailplane fowler flap mechanism | slope445 | Scale Sailplanes | 23 | Jun 01, 2020 02:08 PM |

| Question | Different Hinge design for Flap and Aileron | old1104 | Sailplane Talk | 17 | Nov 30, 2016 11:58 PM |

| Discussion | Can I get some advice about this flap-rod mechanism? | alex.g.94 | Electric Plane Talk | 16 | Jan 25, 2016 11:45 AM |

| Question | Basic flap design\mechanism question? | xkubr | The Builders Workshop | 6 | Nov 19, 2011 02:40 AM |