|

|

||

|

|

Quote:

Stefano has done good work with devCAD. It brings 3D modeling down to a level where I can enjoy it and turn out decent results. -=Tom=- |

|

|

|

||

|

|

|

|

|

|

|

Lunchtime #5--Flat Tail

Hi Mike--thanks very much for making the connection. Your little TBD is sweet like pie! Very inspirational.

Heya, Tom! Real short lunch today. I made a flat tail that would be fine for a smaller model. My 30" fleet uses simple flat tail parts. The 45" stuff looks better with some shaping. But for this 60 incher, she'll need a tail with some proper airfoils. But not in 15 minutes. So the flat tail will at least help move the fish toward looking like a Devastator for now. Paul |

|

|

|

|

|

|

|

|

I've been using fusion360 from auto desk it's also free for hobbies and commercial use under $100k revenue.

It's a bit like inventor but it has an integrated CAM and 3D export function. Downside to the program is that it does not do weldmets or a proper drafting drawing function which makes it harder to send dimensioned drawings to a fabricator. Already learning some good stuff from this thread. |

|

|

|

|

|

|

|

|

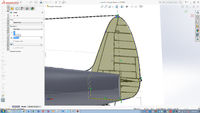

Lunchtime #6--Wing

Man, almost got pushed back to page 3! Not as much lunch time lately. Been working a weird schedule after bringing a new pup home. Real good dog but cutting into my RC time

Next step on the TBD was to get a wing built. Its currently based on an SD6060 airfoil. This was recommended by my NASA buddy AlienTech. But for right now its a placeholder until the P36 flies with the SD6060 and demonstrates good performance. But that's one of the neat things about CAD. We can drop in a new airfoil later with minimal effort. Same thing with the stall control. Right now the model shows two degrees of washout. But as Fuzz has mentioned, reducing the wingtip airfoil thickness is also an option. I'll do that later during a later lunch break and reduce the twist. Wing tip is next on the punch list. But tomorrow is an all day offsite. Paul ImagesView all Images in thread

|

|

|

|

|

|

|

|

|

Hiya' Koh, On my way to the Adirondack's this morning. First stop 4hrs away. Going to be a long day... Put the root at +2deg and the tip at 0 to the fuselage datum.

Fuzz |

|

|

|

|

|

||

|

|

Quote:

You will not be disappointed with the SD6060. Very good flight range, we have used it on 200+ MPH pylon racers down to some slow flying electrics. Red has definitely pointed you in the right direction. I use Solidworks and noticed that your lofts of the airfoil keep the TE as a single point. In the past I have not had much success lofting this way and I am wondering if there is a trick that you can share. Most of my lofts of wings I clip the end and leave a .01" thick vertical wall at the TE. I am wondering if you have experienced anything like this in the past. DK |

|

|

|

||

|

|

||

|

|

Quote:

-=t=- |

|

|

|

||

|

|

|

|

|

Hi Paul, I think the thing to check is whether the wing looks right from the front / forward quarter. The TBD had a very thick airfoil with a large nose radius - not the sort of airfoil for high performance at model scale - but electric model airplanes are usually not short of power and never need a long range or endurance that an airfoil like SD6060 would confer. The TBD wing seems to dwarf the fuselage viewed from the from the front. I think the question is does the wing look scale? CAD renderings ought to be able to show whether the model will capture the look of the TBD wing, John

|

|

|

|

|

|

|

|

|

Thanks, Fuzz--that's pretty much where we're at. Adirondack is for work? At first I was hoping you were off fishing.

DK--thanks for the preview on the SD6060. That's good news. It looks good visually and the numbers do to. Thanks for question on the TE--its worth some attention. The SD6060 profiles are clipped at the TE. Rather than coming to a point, they are both truncated at a 1mm thickness. That makes it easier on the laser (that fine point would be burned off anyways) and the builder (a paper thin balsa TE isn't very durable). Hi Tom--good question. The FMS metal trunion retracts worked with the SD6060 on the Hawk, but as you know the retracts are only partially embedded in the wing in the Curtiss design. I'll have to check on that but I think I have a couple of things that can work in our favor here. First, by eyeball I think that the chord on the TBD is larger where the retract lives than on the Hawk. And second, rather than thin the tip section we can thicken the root for stall control. Again, this stuff is really easy in CAD. We'll import the retract from the Hawk file and move it around. Fatten the root or swap to another airfoil (USA35 for instance). Find the right answer and hit Save  John--you are right about the appearance of the TBD's high lift wing. It's fat. Another reason to try thickening the SD6060 root rather than thinning the tip. We'll need to adjust the root airfoil as well as the wing's position in the fuselage to get the belly to look right. That may dictate the wing's incidence, too. On the upper side we can get away with murder since that humongous fillet will cover the intersection plus alot more. Hi Alec--no worries! Glad there is interest in this stuff. Not too many lunch hours next week, though! Paul |

|

|

|

|

|

|

|

|

That was on the job, Koh. I had 5 stops delivering. I have never been west of Lake Champlain, into the Adirondack's, before. I have alway's loved mountains.

Fuzz |

|

|

|

|

|

|

|

|

Lunchtime #7--Wing Tip

I managed to get a little time in on the TBD for two of the three work days before Tday. One thing worth noting is that Lunchtime is averaging 15-20min a day on the project. A little time to eat, a phone call here and an impromptu meeting when someone catches me at my desk. Not a bad thing--just sayin that we have about 90min on the job so far.

Today's goal was to put a wing tip on this beast. And that brings up the topic of software stability. You may have noticed that there aren't many dimensions in this model. In real engineering design, there are more design constraints than just copying some outlines. Adding dimensions helps the software anchor things in place. In some cases, the lack of dimensions will result in instability. That may happen when the shapes get really complicated or you try to do too much with a single sketch or operation. So simple is good. On to the wingtip. Like the wing itself, a loft will be formed between two profiles. The first profile will be the end of the wing. The second will be a funny little keyhole on the wingtip plane. We could use a point instead, but the keyhole has made better lofts for me. The guide curves will be made from 3D sketches. They could all go in one sketch, but that has caused problems, too. One sketch for the horizontal guides and another for the vertical should help with stability. Paul |

|

|

|

|

|

|

|

|

Lunchtime #8--Canopy Cut

Next up was the cut out of the canopy. Making this cut can tell you alot about the quality of your drawings, the quality of your fuse loft, or both.

The canopy cut out is driven by the profile and the shape of the fuselage. The result is the top view outline. If the outline isn't right, then you can adjust the profile or tweak the fuselage former sketches. In an ideal world, your 3-view drawing would be 100% accurate and everything would fall into place. But in reality, most drawings are really just arrangements of attractive sketches. This is particularly true of the formers if they are present. For the TBD, the drawing is actually pretty good. It seems that the canopy is pretty close with the exception of the bottom edge of the windscreen. That's a tricky area though. Paul ImagesView all Images in thread

|

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Build Log | 1/32 Scale TBD Devastator Scratch-build | cybermike | Scratchbuilt Indoor and Micro Models | 125 | Oct 10, 2022 08:22 PM |

| Build Log | Scale Build-Off 3: 40" TBD-1 Devastator | JIMA | Scale Kit/Scratch Built | 85 | Apr 04, 2014 05:33 PM |

| Gallery | Douglas TBD Devastator | davidterrell80 | Scale Drawings and Three Views | 0 | Mar 25, 2014 10:31 AM |

| Discussion | Midway TBD-1 Devastator Build | J Morgan | Scale Kit/Scratch Built | 143 | May 18, 2009 05:59 PM |

| Any good paper models of the Douglas TBD-1 Devastator? | Swan | Foamies (Kits) | 16 | May 16, 2005 10:52 AM | |