|

|

|

|

|

Good day Gerald,

I like your paint style better, but it looks like your trim color is above the gunports. Most paintings, models, and research I've seen shows that the gunport level of the hull was painted a contrasting color. White, someshade of yellow, green, blue (Letter of Marque, Jack Arbury book) or red, based on who owned the vessel and what they wanted as a trim on their vessel. The historic notes on the sloop I'm building says she was "black and low" but I believe that is when she was trying to run British blockades at night. So she wouldn't want to draw attention to herself. Yours is looking really good, post more pictures soon! Jason |

|

|

|

|

|

|

|

|

|

|

hello jason

thank you for your friendly words. thats right, the most clipper have the trim color above the gunports. but i have oriented me by the real baltimore-clipper "pride of baltimore" and by this ship the color band is under the gunport. regards gerald |

|

|

|

|

|

|

|

|

Ahhhh...yes...

I also have mine (black trim) under the gun ports.

Question...what is the maximum amount of rudder play that would be considered acceptable. I have about 1 inch of travel/play measured with a ruler at the aft end of the rudder. It seems the brass rudder shaft has some wear. Capt. Slick |

|

|

|

|

|

|

|

|

Well as long as you have research backing you up. I stand corrected.

Jason |

|

|

|

|

|

|

|

|

Brooks...

...I looked at it again this morning and I actually have closer to 2 inches of side to side play when the rudder is amidships (almost 1” each way), and about 1 inch back toward amidships when hard over to starboard or port. I've always had some rudder play but it is getting worse. I may need to figure a way to re-gear with a harder shaft or do away with the gears all together and try to go with the standard servo, to rod, to arm setup.

Capt. Slick |

|

|

|

|

|

|

|

|

Whoa - definitely too much play. Just guessing here, but one fix that might be possible: Assuming the lower brass fitting is tightly attached to the hull and that the rudder shaft fits in it well and rotates freely without slop, then you can fix any slop at the top of the shaft by adding a simple bearing plate on the deck or against the transom - whatever. Use about a 1" x 1" square of 1/8" delrin with a new shaft hole drilled into it. Attach that square flat on the deck with the hole centered over the proper location for the rudder shaft. That should get the rudder rotation nice and snug, and then any drive should be able to be attached to the rudder shaft and transfer positive action to the rudder.

My upper bearing plate is hidden as a small grated hatch. See pic. |

|

|

|

|

|

|

|

|

I assume you have checked for loose setscrews. If they have wallowed out some of the shaft, then you might be able to grind new flats on the shaft, either in the same location, or rotated. A single set screw on a round shaft is subject to excessive wear strain. For steam loco eccentrics, 2 set screws, 90deg apart, are required. Mechanically, the double setscrew design is superior (avoid double designs with the setscrews 180deg apart, though).

|

|

|

|

|

|

|

|

|

The shaft is hollow brass with a spline that runs the entire length. It is screwed to the rudder plate...no play there or in the servo. I have no up/down play. The splined shaft engages a metal gear that is driven by the servo and is worn at that spot. My shaft no longer goes through the deck. I cut it off below deck because it was attached to the tiller, and I couldn't have the helmsman holding an operating tiller. I see my only choices as above or replacing the shaft and possibly the entire rudder assembly. No guarantee a new assembly or shaft won't do the same thing with use. Attached is a pic...sorry it's not clear but it is all I have here at work.

Capt. Slick How are your rudders configured on the brigs/frigates? |

|

|

Last edited by Capt.Crash; Sep 13, 2007 at 10:39 AM.

|

|

|

|

|

|

Can you provide a rough sketch of the assembly and/or a pic from the top (deck). Is the mechanism - servo, gears - covered by

the deck and inaccessible? One thing easilt done is fit a brass tube over the end of cut off shaft, solder in place, fill with JB Weld, and then re-work the drive attachment. A pushrod/arm arrangement would be better than the gears for this limited movement. |

|

|

|

|

|

|

|

|

Well…after losing my entire post due to a power failure during upload, let me try it again.

I am at home and pulled the assembly for another close inspection and cleaning. I can find no slop in any of the assembly except a little at the shaft /gear contact patch. I slid the shaft down to a fresh contact spot and it is about the same….a little sloppy and is the cause of my problem. I don’t think there is anything I can do about it short of come up with a different shaft with a tighter tolerance. It is inherent to the design. I am at home and pulled the assembly for another close inspection and cleaning. I can find no slop in any of the assembly except a little at the shaft /gear contact patch. I slid the shaft down to a fresh contact spot and it is about the same….a little sloppy and is the cause of my problem. I don’t think there is anything I can do about it short of come up with a different shaft with a tighter tolerance. It is inherent to the design. I don’t see a better way to build this mouse trap either…it is pretty ingenious! I have to be able to pull the shaft out the hull and can have nothing unremovable attached to it. I may be stuck with what I have. I still have a lot of rudder and the ship tracks very well thanks to the hull and ballast plate design. I don’t think it is contributing to my tacking problems. I attached the pics for your viewing pleasure. Capt. Slick Philip...if you don't want these pics posted...let me know and I will pull them...

|

|

|

Last edited by Capt.Crash; Sep 13, 2007 at 06:22 PM.

|

|

|

|

|

|

HH -

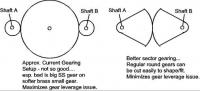

I'm no expert, but who cares... here's what I think. The current gear arrangement s*cks. A big gear driving a little gear, especially a little gear with a big load (like the rudder splined shaft) is bad design. I think my sketch shows a simpler, more mechanically/load balanced approach that can easily be retrofitted to your system. From the pics, it looks like the small brass pinion drives a large SS transfer gear that then drives a small brass pinion. The overall ratio looks to be 1:1 - both pinions with the same number of teeth. The bad part is the big, hard SS gear driving the small soft brass pinion (the splines on the rudder shaft). Easily fixable, I think, with sector gears. Get two nylon gears of the same diameter, such that the meshed diameter matches the shaft A to B center-to-center distance. The gears are going to rotate only about +/-30 degrees, so you can sector them - just cut away the teeth and portions of the round gears to fit the space you have, leaving at least the 30 deg plus a little extra to prevent out-of -mesh at max travel. Save the current shaft by oversleeving it with a brass tube soldered on. Use the other current small pinion the same way - oversleeve it to serve as the shaft for the new gear. Resize the new gear shaft holes for the oversleeved shafts. Easy to do cuz they don't have to be perfectly concentric for the slow, limited range movement in this application. Hope this might work for you. The rudder plat you currently have is unacceptable. |

|

|

|

|

|

|

|

|

Dan...your idea is great...only problem is how do I make the new gear (on top of rudder shaft) removable so I can slide the rudder shaft out? There is an accessibility issue here too. That shaft goes into the little tube at the end of the rudder assembly block which is inserted into the transom. A very small part of the shaft protrudes out the top of that tube just under the deck and in my case partly in the transom. The part of the shaft that has the contact patch with the gear is actually cut out of that shaft tube (look carefully at the pic) that inserts into the transom. The only way I might and I say again…MIGHT…be able to add to it is if I have enough room…which I doubt…and if I cut a hole in the deck for access. I can do the hole and make it like your tiller hatch…but again I don’t think I have room to even slip a gear over the shaft…it’s that tight. You see where my tiller shaft is? The rudder shaft is just under it. It used to be attached to the tiller (slide inside the wood) but I cut it off. You know Philip had to have pondered on this one awhile…and his solution is brilliant but…I think the biggest problem is the brass components. I think the other gears may not be stainless...aluminum? Every thing is very tight, only the smallest of movement, up to the brass shaft.

My mind is working on how to cut the top off the shaft and attach a hard metal replacement extension gear of the same rudder shaft diameter. I could drill, thread and bolt the new piece on or even braze it on but I would need to find the perfect part. Again the biggest problem with this whole thing is space…there just isn’t any! |

|

|

Last edited by Capt.Crash; Sep 14, 2007 at 07:45 AM.

|

![Name: steering-gearP5287958[1].jpg

Views: 266

Size: 67.5 KB

Description: Name: steering-gearP5287958[1].jpg

Views: 266

Size: 67.5 KB

Description:](https://static.rcgroups.net/forums/attachments/4/3/6/4/2/t1477805-93-thumb-steering-gearP5287958%5B1%5D.jpg?d=1189692296)