|

|

|

|

|

Arrowking,

Here's a good thread on the 16..It is an older thread but the guy uses really nice techniques for forming his foam and you might find some useful information within..Thomas Nelson is the thread starter..I think there are 2 built in the thread.. https://www.rcgroups.com/forums/showthread.php?t=380552 Hope you are able to find some useful info... Take care......................Chris Also,I think I have searched and found another thread or 2 on this airframe but will have to dig through a few comps to see if I can "re" discover them...lol.. |

|

|

|

|

|

|

|

|||

|

|

Heres something to get the creativity in high gear..I really like watching one of these on the aircraft I'm building..you get to see different paint schemes are armament packages..Also scale details to name just a few benefits of Discovery Wings, Great Planes or Modern Marvels...

Discovery Wings F16 Video...51 minutes of footage!!!

|

||

|

|

|||

|

|

|

|

Thread OP

|

I've got a total wing area of 0.1418 m^2. Assuming a wing loading of 40 kg/m^2, that would make a plane that is 5.6 kg. At 5.6 kg that's a thrust to weight ratio of ~5:1. I think 5.6 kgs is on the heavy end of the mass I'm expecting and hoping for. I'd like a much lower thrust to weight ratio. I still need get to an estimate on the weight of my design to date... Maybe I'll just bite the bullet and switch to a 70 mm fan.

|

|

|

Last edited by arrowking; Apr 14, 2012 at 04:19 PM.

|

|

|

|

|

Thread OP

|

Small tally of hardware I've weighed.

Motor + fan 150 g 70A esc 50 g 1800mAh LiPo 150g (undersized but all I've got to measure atm.) retracts 200g 6 metal gear servos 150g These are all of the big ticket items, not counting the airframe or the fiberglass duct. It's looking like 700g for just the hardware. I'm not sure whether to be happy, or concerned. I must be able to build the airframe to under 1-2kg, I've weighed all of my foamies and they are all under 1kg. My old PT 40 trainer is like 3 kg with nitro engine and all. What do you guys think? I'll be tied up for a few weeks, will update when I've made some progress. |

|

|

|

|

|

|

|

Thread OP

|

I've started up work on the design again. Just wanted to post a few pics.

These are pics of the 3D model's fuselage, and the canopy assembly on top. You can see where the electronics compartments in the fuselage. The hole is wide and depth enough to house a 4500mAh 4S battery and is plenty long. |

|

|

|

|

|

|

|

Thread OP

|

Most of the bulkheads in the fuselage assembly without the cone or canopy. There will likely be less bulkheads than this, I might also make most of these out of 6 mm foam. It would make construction much quicker and likely lighter.

|

|

|

Last edited by arrowking; Jun 08, 2012 at 09:54 PM.

|

|

|

|

|

Thread OP

|

So I've decided to make the airframe as light as possible. The bulkheads will be made of 6 mm foam except where extra strength is needed. I think I'm going to hotwire the wings as foam cores stiffened up by carbon fiber. I'll be using half of the bulkheads shown in the last screen. I'm also going to build a stripped prototype first, no gears or rear belly fins for belly landings. This should get me a working model sooner. Need a hot wire cutter...

I'd like to keep this model as light as possible, I wonder if I can keep it at < 1kg... |

|

|

|

|

|

|

|

Thread OP

|

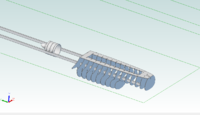

Just showing some progress. Gonna work on making the ducts next. Have been paying attention to HoverorDie's thread

https://www.rcgroups.com/forums/show...584319&page=10 as well as IngleSingles' https://www.rcgroups.com/forums/showthread.php?t=805557 Here's a discussion on fiberglass ducting. https://www.rcgroups.com/forums/show....php?t=1620479 This will be the first time I build a fiberglass duct... |

|

|

|

|

|

|

|

|

Nice design work. Don't underestimate a 64mm fan. I regularly cut down WeMo minifans to 66 & 64mm. I make the shrouds from a double layer of 1/64 ply. In yrs past, I have been able to fly many 70mm designs with the smaller fans. Many were on a light 4s-2200 system. An HET 3w gives 32A@430W. And the 2W20 about 700W. Now, I have been changing over to motors with a 2200-2300 Kv and going with a 5s-1800. Only 27A@650W.

The whole idea is for a light system that does not need full power to carry the weight of a higher Mah pack. Next, I'm moving to 1900Kv motors and 6s. The packs would only need to be 1800Mah or smaller, due to the amps being down to approx 20A. With the watts around 700. Fuzz |

|

|

|

|

|

|

|

Thread OP

|

Been working on the design of the plugs to make the ducts I want. The intake duct has some interesting curves, this will make saving the plug difficult. It looks like I'll be making a 1 time mold that I'll dissolve with acetone to get my duct.

I'm making the plugs out of 2" foam with 6 mm fan-fold foam spacers which have duct cross-sections precut. The plan is to hot wire cut the bulk off and sand down the rest... Should I putty the duct for a smooth finish? I've gone with the replaceable fan design used by IngleSingles, the exhaust duct is 2 pieces. Much better idea than what I had planned. https://www.rcgroups.com/forums/show...805557&page=14 |

|

|

|

|

|

|

|

|

It's not a good good thing, to use the lost foam method, for duct forming in the normal sense. Even if you use spackle or some other putty, unless you PVA and wax the mold, to release the putty later from the formed duct, you will have a moon scape on the inside.

For short term forming, I wrap the duct with packing tape. Then a few coats of PVA. I cut the duct off with one slice and re-assemble with a strip of glass, using CA. The plug is still usable for a second duct, if needed. Beginning here: https://www.rcgroups.com/forums/show...0&postcount=33 I used this method for my Cutlass. Use one wrap at a time. If you spiral the tape, it will crease. And the bare foam gets spackle and a coat of white glue or Mod-Poge puzzle sealer, before wrapping. Fuzz |

|

|

|

|

|

|

|

Thread OP

|

Checked out your thread, nice work.

My plan was to wax the plug and melt the foam with acetone which was recommended to me. My duct is "irregular" like yours and the plug won't simply just slip out. I'll definitely have to cut my bulkheads just to install intake duct  . . I'll put a bit of thought into your idea about making a single slit in the duct to extract the plug without destroying it. Might be a good idea in case I ever want to make a 2nd one... |

|

|

|

|

|

|

|

|

If you PVA the plug, Acetone will not affect the PVA. Later, you can immerse the duct in warm soapy water and the PVA will release the melted remains of the foam. The surface of the duct ID will be as smooth as you made the plug OD.

I know your concern, some designs just require that you build around the ducting. Altho, I still find myself worked into a corner, thinking I could insert the ducting at anytime. Only to require segmenting a few bulkheads. The suggestion of the limited re-use plugs was, I find it's easier to lay up another set, than make a whole new plug. A little crash and a crease means a new duct. Good luck, with what ever method you choose. Fuzz |

|

|

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Sold | F-16 and F-86 80mm edf airframes | drats | Aircraft - Electric - Jets (FS/W) | 3 | Jul 03, 2012 03:13 AM |

| For Sale | F-16 and F-86 80mm edfs | drats | Aircraft - Electric - Jets (FS/W) | 3 | Jun 28, 2012 10:24 PM |