|

|

|

|

|

Hmm, it should just pull off, mine did.

|

|

|

|

|

|

|

|

|||

|

|

Phoenix Evolution Slope Soaring

Here is a video of my Phoenix Evolution slope soaring.. It is the same as the 2000 but with the 2.6 meter wing (which is one heavy bugger!). I would guess that a 2 meter wing would be even more fun on the slope. I have the usual mods like upgraded motor/esc, 3A BEC, dubro clevis hardware. I was running it without a motor or Battery but it required 2oz of lead to balance... Almost a wash in weight difference between motor vs. no motor. I have a headsuprc 2830-09 motor. Amazing efficient motor that will still spin a 10 inch folding prop. I did'nt use the motor at all for sloping and after four hours of flying the 3s 2200mah battery was down to 11.5v. I flipped the servo tray upside down for more servo arm clearance and added carbon fiber pushrods all around. The fuselage is painted with red Krylon "fusion" paint, with numberous coats of clear topcoat. Packing tape on wings and tail. Warning the video is way too long!

|

||

|

|

|||

|

|

|

|

|

Wow, that's cool! I also have the Phoenix Evolution and fly with the short wings on.

How do you throw your Evolution around like you do with those long wings? When I fly with the long wings on, my Phoenix Evolution is slow to bank and turn. Do you use a lot of rudder? |

|

|

|

|

|

|

|

|

Isn't that cool!

In such a head wind the control surfaces have a lot of air moving over them. (20mph) Most of the movement on the slope (when I slope In such a head wind the control surfaces have a lot of air moving over them. (20mph) Most of the movement on the slope (when I slope  ) is timed "leverage". Bank it so the wind really cranks up your air speed and then up elevator. The Danger spots that I experience on the Evolution is the downwind handling (torward the slope).. you need to keep the nose down or nothing happens..( either use rudder in the bank or elevator to push nose down.) I use my rudder on the height of the high bank turn to whip the tail around and sometimes on the cross slope ride to keep the nose into the wind. The Phoenix's wings are wide, so a tip stall is pretty hard to induce unlike a high aspect ratio wing,. ie FOX or ASW, which I also fly on the slope. There is nothing like sloping... even better with a group of friends who are flying in close proximity on the same lift. ) is timed "leverage". Bank it so the wind really cranks up your air speed and then up elevator. The Danger spots that I experience on the Evolution is the downwind handling (torward the slope).. you need to keep the nose down or nothing happens..( either use rudder in the bank or elevator to push nose down.) I use my rudder on the height of the high bank turn to whip the tail around and sometimes on the cross slope ride to keep the nose into the wind. The Phoenix's wings are wide, so a tip stall is pretty hard to induce unlike a high aspect ratio wing,. ie FOX or ASW, which I also fly on the slope. There is nothing like sloping... even better with a group of friends who are flying in close proximity on the same lift.  This hill is really a small hill (30ft) and not very good for sloping...but it's still a flyable site and close to my house so I can get out in the best window for it's conditions. This hill is really a small hill (30ft) and not very good for sloping...but it's still a flyable site and close to my house so I can get out in the best window for it's conditions.

|

|

|

|

|

|

|

|

|

Improving Cooling Air Flow to Stock Motor & ESC

Friends,

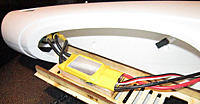

I've just received a Phoenix 2000 Version III kit from HK, and have started work on it. My intention is to fly it first with the stock motor & ESC; upgrades are always an option later. (I'll be installing other servos for the ailerons, elevator, & rudder before flying.) From reading many comments about the stock motor overheating and the stock ESC failing, I decided to start there. The kit as supplied does NOT have the cooling airflow vents in the motor mount phenolic plastic plate cut out on the motor side of the plastic firewall, and the openings were also not cut in the nylon plastic firewall area of the fuselage. I started by removing the battery tray and motor to remedy this. The photos below show the result. I next enlarged the intake air vent openings on the sides of the fuselage to allow more airflow over the ESC & flight battery. (I'll cut larger exit vents just aft of the wing mount position on either side of the fuselage later.) Next I worked on the ESC & it's mounting to improve the effectiveness of the cooling air flow on it. I first cut away selected sections of the thick rubber heat shrink covering over two areas- the main MOSFET heat sink aluminum plate on the ESC's top surface, and over the two 3/8" square BEC voltage regulators on the opposite side. I then cut some thin sheet aluminum to size for an added heat sink for the two voltage regulators, and glued it in place solidly in contact with the voltage regulator's cases. Keeping the ESC positioned effectively in the cooling airflow was the next aspect to deal with. I used two balsa rails to mount the ESC to the lower surface of the battery mount tray with airflow space between. I simply glued it together with thin CyA glue & baking soda; the results are shown in the photos below. The rudder was the next issue that I focused upon; I decided to try stiffening it and reinforcing the lower end of the existing 'live' EPO hinge before adding anything else. I used an adjustable temperature soldering iron with an appropriately sized tip to melt in two channels for the ~1.5mm CF side stiffeners, and then glued the CF rods in those slots flush with the surface. A third CF rod section was inserted into the foam just across the top of the control horn mount area. I'll glue the control horn to the EPO foam once it's mounted to keep the foam from fatigueing where the control horn compresses the foam- (I've seen this happen on another foamie glider before.) More later. VIKING ImagesView all Images in thread

|

|

|

Last edited by viking60; Nov 17, 2012 at 08:43 AM.

|

|

|

|

|

|

The ~3/16" thick trailing edges on the elevator, rudder, and wing's trailing edge are something that offers room for improvement. So I took my foam drywall sanding block (3M brand bought at Walmart) to the elevator & rudder (after drawing a center line on each trailing edge.) Yes, it takes time to do, but these EPO foam trialing edges can be nicely thinned down to under 1mm thickness.

I then ironed on Fluorescent orange Oracover on the elevator's trailing edge, wrapping one piece continuously from top to bottom. After working over the rudder's trailing edge, I ironed on some 1.5 mil clear Doculam film. Both of these materials adhere well at temperatures which are low enough to not distort the EPO foam- the trick is to just keep the temperature low (~260 degrees F ) & not get in a hurry. The photo below shows the results. Doing the wing's entire trailing edge will take some time, but before I go further, I'm inclined to go ahead and do a thorough job of it. I'll shape that towards the existing bottom surface edge. From everything I have experienced over the years, I'm thinking that the improvement as far as reduced drag & improved glide efficiency should be worth the effort. I want to do this task before painting the wing's bottom with Krylon Fluorescent Orange paint.... These aging eyes do like a highly visible bottom when it's riding a thermal waaaaay up there, trying to speck out amongst the clouds!  VIKING |

|

|

Last edited by viking60; Nov 17, 2012 at 08:49 AM.

|

|

|

|

|

|

Adding the "Visibility" to the undersides after thinning T.E.

Friends,

Today, I went ahead and thinned the wing's entire trailing edge to a more or less sharp edge- less than 1mm thick. I started by removing some material with a fresh Exacto blade, and completed the task using the 3M foam sanding block. The resulting airfoil is blended into the original contour about 1/2" back from the aileron & flap hinge line. Once the thinning was complete, I ironed on the 1.5 mil clear Doculam film over the entire area which was reshaped; this covering also wraps the trailing edge & extends on the underside another ~1/2" to result in a very durable thin trailing edge. I've decided to set up this wing for Spoileron function for landings- it works well for shortening landing approaches on my Multiplex Easy Glider & my Viento / Siren warmliner, so it should do the job nicely on this Phoenix 2000. So I used more of the laminating film to immobilize the flaps and seal all of the hinge line gaps and servo cutout holes. This leaves the aircraft about 1-1/4 ounce lighter with fewer drag-producing structural elements on the inboard section of the wing. I installed Turnigy TGY-90S metal gear servos for the ailerons; I'll use two more for the rudder and elevator, and save the four stock servos for another light foamie project. I closed the excess openings around the aileron servos with tape & masked the servo arms. The next step was to add the high visibility Krylon Fluorescent Red-Orange paint to the underside of the wing and horizontal stabilizer, and to the entire vertical stabilizer. Having the entire underside a brilliant color really offers my eyes the best visibility at extreme distances. For now, the top of the wing can stay white... that's not the side I'm seeing when I'm flying and hunting thermals!!  The photo below shows the results as the painted parts slowly dry on a cool day in Colorado's high country. I may also apply some fluorescent red tape to the belly of the fuselage to complement the other painted undersides, to give a good view of this fine glider from below. More Later. VIKING |

|

|

Last edited by viking60; Nov 17, 2012 at 08:55 AM.

|

|

|

||

|

|

Quote:

Did the Krylone Fluorescent Red-Orange paint harm the foam? |

|

|

|

||

|

|

|

|

|

HoosierGuy,

No, the EPO type foam was not bothered by the paint at all. It will eat the EPS type foams like Bluecor if it's applied wet / heavy, but EPO and EPP foams aren't damaged by the solvents in this paint. I had used it previously on my EasyGlider, and the color has remained bright for years. It bonds to the Doculam laminating film well, too. I'll be installing the receiver, control horns & linkages this morning. I'll check the plastic control rod clevises carefully; the ones included in this version III kit may be better than the earlier ones. I'll be installing silicone tubing keepers on them if I do use them. VIKING |

|

|

|

|

|

|

|

|

Rudder hinge enhancement

Friends:

On the rudder, the lower end of the EPO 'live hinge' is a vulnerable area. Before painting it, I decided to employ a variant on the early free flight model's sewn thread hinges technique. I got out a long thin needle and some heavy strong white nylon thread, and began 'sewing' back and forth from the vertical stabilizer to the rudder, passing each thread section through the existing thin hinge area. I used thin CyA glue to lock each 'stitch' in the EPO foam. NOTE: ( If you do this, you have to be careful not to put too much tension on the thread, as it'll cut through the EPO foam. Lock each stitch with glue as you go along.) Once the sewing was completed and all of the thread stitches were glued to the EPO foam with the CyA glue, I hauled out my bottle of "Dave's Flexament", a fly tying glue that remains flexible. I applied a thin coat of this to the lower 1" of the 'live hinge' area where the thread stitching had been done. TECH NOTE: (I've heard that this 'Flexament' may be nothing more than Shoe Goo or Goop thinned with a solvent; While MEK and MIBK are used in the Flexament product, the slope combat glider guys thin their Goop with toluene. Neither of these solvents will bother the EPO or EPP, but they are really tough on EPS foams- they'll dissolve it.) The result is a VERY STRONG yet flexible lower hinge area for the rudder control rod to act against. VIKING |

|

|

|

|

|

||

|

|

Quote:

|

|

|

|

||

|

|

|

|

|

Close to ready to fly!

Friends,

Here's a look at my finished Phoenix 2000 with it's fluorescent orange bottom, very close to it's maiden flight later this morning. All that remains to do is to add the cooling air exit vents on the sides of the fuselage somewhere aft of the battery position, and to also enlarge the hole in the aft end of the fuselage. A section of 2" wide tape was applied to the fuselage's belly to add visibility and also offer some scuff protection on landings. Flying weight is at 41-1/2 ounces. To balance on the 70mm back CG marks, the 3S 1800 Nano-Tech battery has it's front edge aligned with the battery tray's front edge- easy to position on the velcro. I've now assembled a vented spinner midpart with a set of Freudenthaller 10.5x6 blades to fly on this bird. I want the cooling air to be directed by this spinner's 'ram air' center intake directly in through the motor mount vent slots & back through the interior of the motor's case. This is a 40mm spinner for a 3mm motor shaft, H.K. part # 6357. while a 45mm spinner would match the nose of this fuselage even better, this is one which I had on hand from a previous order, so it's what I'll be flying for now. By drilling holes with a #52 drill bit in the control horns, and with a #53 drill bit through the servo arms for the Z-bend ends of the stock control rods, I'm able to use the linkage rods, control horns and clevises which came with this version III kit. I'm using ~1/2" long sections of large silicone fuel tubing as clevis keeper sleeves. The plastic material itself seems to be flexible & resilient, so all that's needed is to keep them solidly latched... the tube sleeves do that nicely. VIKING ImagesView all Images in thread

|

|

|

Last edited by viking60; Nov 22, 2012 at 12:48 PM.

|

|

|

|

|

|

Viking,

Gezz, you've certainly done your homework and the work on getting your P2K spot on. I wish you all the best for the maiden, and God forbid all that work you've done on cooling and colouring that you don't over-heat anything or lose orientation and spin the thing in on fire.  Be sure to have the #16 Cams strapped on it, or aimed at it so we can see the results for better or worse. - All the best! -B! |

|

|

|

|

|

||

|

|

Quote:

|

|

|

|

||

|

|

|

|

|

FLIGHT PERFORMANCE REPORT

First flight went well- (that is, up until I lost it in the sun after about ten minutes of flying... it was certainly not a problem with how the aircraft is flying, but with my aging eyes, I'm sad to say...) Prior to that incident the flight was very good, from the first launch & climb-out. After initial trim fine-tuning & cruising about, I adjusted the throttle > elevator mix setting on my RD8000 transmitter during successive full throttle climb-outs to minimize the zoom on climb. I found the glide efficiency performance good; elevator, aileron and rudder response is clean and effective, typical of other similar 2 meter gliders I've built & flown. Climb performance of the stock motor with the 10.5 x 6 prop was certainly very adequate for what I was looking for with the Phoenix 2000; the stock motor & ESC that came with this Version III kit (shipped from the H.K. USA warehouse in early November 2012) are performing as they should in a 41.5 ounce glider. (The 3S 1800 Nano-Tech battery packs are known for holding a high voltage under load, and that might contribute to having decent climb-out performance too. It's not a competition or race type design, after all.) FOOD FOR THOUGHT: Maybe the ESC that's being produced and supplied now is built better than what was produced for the early versions of the kit... that's a possibility. And maybe investing the extra efforts to provide adequate cooling airflow through the motor and mounting the ESC to the underside of the battery tray for adequate cooling are something that's a good idea, no matter which motor and ESC you choose to fly.  I intended to set up & fly this 2 meter EPO winged glider primarily for thermal hunting & efficient power-off gliding- to be able to climb up to about 400 feet AGL in about 20 seconds, shut down the motor, & glide, using whatever rising air I encounter. I'll fly it on the slopes, too, where I expect it to handle well. NOTE: The canopy fits in place beautifully, & should stay in place nicely. However, the left edge still protrudes enough to catch the very sharply shaped leading edges of the Aero-Naut folding prop blades which I'm using; the quick remedy is to apply a strip of 1/2" wide clear scotch tape in the area before launch. I may see about sanding that edge of the canopy thinner at the area where the folding prop blade catches, to eliminate that issue, & eliminate the need for applying the tape. (The canopy may actually need some careful heating & narrowing on the front end to really clear the prop blades.) VIKING |

|

|

Last edited by viking60; Nov 19, 2012 at 06:32 PM.

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | |

| Similar Threads | |||||

| Category | Thread | Thread Starter | Forum | Replies | Last Post |

| Discussion | Ohhh noo, 2nd flight on the HobbyKing Phoenix 2000 | KillerCut | Electric Sailplanes | 24 | Oct 28, 2020 02:43 PM |

| Discussion | Still having electric problems with my hobbyking Phoenix 2000, Crashvideo | kyrkbymannen | Electric Sailplanes | 4 | Oct 28, 2020 02:37 PM |

| For Sale | HK Phoenix 2000 glider | blk822 | Aircraft - Electric - Airplanes (FS/W) | 4 | Aug 23, 2011 07:21 PM |

| Discussion | hobby king Phoenix 2000 EPO Composite R/C Glider | doomracing | Electric Sailplanes | 3 | May 31, 2011 10:09 PM |