Archive for June, 2018

Comments (0)

Add Comment

-

Views: 60

Views: 60

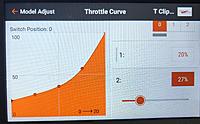

This is the approach power curve where the first point on the curve is the 20% throttle position. -

Views: 48

Views: 48

Here is the windmilling prop curve where the lowest throttle position of 15 percent just turns the prop over. -

Views: 71

Views: 71

This is the normal throttle curve. The lowest throttle position is 0 and stops the prop by using the ESC BRAKE program.

-

Views: 56

Views: 56

This 20V Bauer pack uses screws easily removed to seperate the case. -

Views: 58

Views: 58

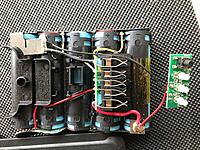

5 cells with the black plastic cell holder. -

Views: 50

Views: 50

Lots of wires to use or remove. LED show charge status using a Baur drill that comes with its charger. -

Views: 64

Views: 64

Some possible radial designs. The Sortaskorsy flying boat (either water or ground) would work well with the radial battery configuration. -

Views: 60

Views: 60

222 grams for 5 cells INR 18650 type More research needed on amp draw and heat. -

Views: 53

Views: 53