Posted by VicT |

Apr 14, 2024 @ 11:13 PM | 1,022 Views

I am concerned that I will pull the aileron wire(s) out of the crimp connectors when removing the wing from the fuselage. I tried to repair a broken wire from one crimp. The solder held but the blob was too big for the crimp connector to be locked into the plastic housing. The board has exposed contacts that are 1 mm spacing and I don’t want to risk a bad solder joint.

To reduce damage to the wires and crimp connection I have installed a loop of spider wire fishing line into a hole that I drilled in the white plastic housing.

Hemostats or needle nose plyers could be used to remove the connector with out stressing the wires but this pool string works just as well.

Posted by VicT |

Apr 10, 2024 @ 06:21 AM | 3,392 Views

Mystery is a good name until I find out the original name. I’ve finished the retract repair and will check the mechanical operation and the prop clearance when level. I have a power 46 temporarily on standoffs and looking at similar Senior Pattern Aircraft (SPA) designs for power choices. From a past post:

https://www.rcgroups.com/forums/show...5&postcount=49

Posted by VicT |

Mar 28, 2024 @ 06:58 AM | 5,609 Views

I got the Spinnn from clubmember Jim who could not complete the installation of servos and a receiver in the very tight plastic fuselage. The hollow molded wing with flaperon servos is a high performance motorglider that is fast but can slow down with camber from a DX or NX TX.

Rc groups has reported that the ESC can over heat and cause loss of power to the receiver. To prevent this the recommendation is to not use full power. This can be done by programming the TX throttle limit.

I used a wattmeter to measure the 11 A ESC and stock motor and prop that was installed.

With a charged 2S 300 JST lipo used in the UMX Conscendo: The NX10 Spinnn program was partially set up using a Spektrum AR410 RX with no telemetry or SAFE. With the case removed it fits in the elevator and rudder servo area of the fuselage.

8.8 A, 6.1 V, 54 Watts

The thrust seems enough for vertical acceleration.

IN Comparison……

Wattmeter tests on UMX Conscendo 2

There are no specs on the motor and prop with any lipos. So here are mine using a wattmeter

With a fully charged 3S 300 30c SMART lipo:

6.4 amps, 11.1 volts, 72 watts

With a fully charged 4S 300 30c lipo

9 amps, 16.2 volts, 134 watts.

Servo loads before and after full throw:

Elevator: .17 to .23 amps

Ailerons: .17 to .26 amps

So the brick ESC could power the Spinn motor and prop on 2S at 8.8 amps which theoretically could be reliable on short 5 second climbs

Note ; the spin 11 A ESC got slightly warm but the black plastic spinner got slightly warmer from the motor that is attached to it.

Posted by VicT |

Mar 25, 2024 @ 01:37 AM | 5,428 Views

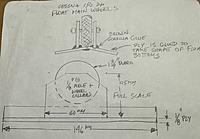

The floats work fine on water and on land. There is plenty of power on the stock power plant and prop with 6S for grass and Geotech runway operations. The plastic float bottoms allow sliding like an airboat but reverse thrust tilts the aft end of the floats into the surface and prevents reverse taxi. So I am adding wheels to solve this problem and to protect the plastic when concrete or asphalt operations are used. The main wheels will be placed on the floats so as to prevent tilting but still allow take off rotation. The final design will be either taped or bolted to the float hull for quick installation and removal. The nose wheels will be removable by removing the wheel collars. A separate steering servo and tiller will steer the left nose gear and the right nose wheel is a castor type design.

Posted by VicT |

Mar 23, 2024 @ 07:22 AM | 6,063 Views

I modified the UMX Radian with landing gear when operating inside a gym. Instead of hand launching and belly landing the gear allowed me to taxi out to a take off area and back into the pits with out getting out of my seat. I’ve made similar gear for the UMX Conscendo.

The wire came from a foam model that had a pushrod tube. The diameter is 1.2 mm or 3/64”. I used a Dremel cut off tool to make a drill bit from the wire and drilled next to the plastic belly skid. I angled the drill so as to penetrate the plastic battery holder. I then bent the wire about 90 degrees forward to nose 33 mm. This portion acts as torque rod. I then bent the wire 90 degrees to form the gear leg. I then bent the wire 13 mm to support the skid. The skid can be made from a discarded credit card. I used plastic from a milk bottle that is .68 mm or .027” thick. Ideally material that is the thickness of the wire will work better. The teardrop shaped skid is 85x27 mm. After bending the wire into shape I drilled a hole for a small screw to secure the wire next to the belly skid. Final bending of the wire was done with two sets of needle nose pliers. After final shaping I used a Sharpie pen to mark the skid for drilling out a slot to support the wire. I used a drill bit a little larger than the wire. The wire is laminated with tape of your choice. I used Teflon PTFE glass cloth tape. A #11 blade or small box cutter is used to trim the tape. The gear can be unsnapped and stored in the cardboard box when needed for hard surface use such as concrete, asphalt, Geotech fabric or gym floors. There is no tailwheel and the aft tailskid protects the foam fuselage. When the fuselage is level there is about 9 mm of prop clearance. The model now weighs 115 grams with out a battery. This includes added plastic paper that is used to enlarge the rudder area. Flight and ground testing will be next.

Posted by VicT |

Mar 19, 2024 @ 04:25 AM | 6,006 Views

The flight control hinges on the UMX Conscendo are a combination of foam and clear tape. Looking at them with a magnifying lens they are the best I have seen. There is no slop in the vertical or horizontal direction. Each of the 6 hinge tapes on the bottom and top are perfectly aligned and most likely are applied by machine in the manufacturing process. When my model experienced high speed flutter the hinges failed. This was caused by adding increased elevator area to improve pitch at low speeds. Since then I have moved the ball link bolt to the inner most hole on the elevator horn.

At first I tried to apply double sided tape similar to the iron on Monocote type hinges used years ago. On larger models it’s much easier and the sticky outside tape can be covered with regular clear tape. However I found that aligning the elevator and stab surfaces was difficult so I abandoned this technique.

I tried using Tyvek paper hinges and regular CA however the CA was melting the foam. I tried odorless foam safe and kicker and this stuck but I did not want to work outside to avoid the toxic fumes that you can’t smell.

Next I tried sewing using fine thread but found that it was tedious and I was not satisfied with alignment and tightness.

My last technique is similar to CA hinges that are available and pre cut. However I did not want to use that stiff material so I am using plastic paper from a Fedex Office (2481 Sheet Card Stk 11x17 inches for 40 cents).

...Continue Reading

Posted by VicT |

Mar 17, 2024 @ 11:09 PM | 5,026 Views

The manual states that the UMX Consendo weighs 111 grams with out a 2 or 3 cell lipo. With the Radian wing the weight is reduced 30% to 77 grams. The wing tip dihedral will behave similar to the UNX Radian using the Conscendo rudder only. Of course there will be no SAFE wing leveling or aileron rolls as there are no aileron servos in the wing. With tip dihedral wing leveling will be automatic like the original Radian. The Radian wing section is much thinner than the stock Conscendo wing and will have less drag and better glide performance. I have not calculated wing loading differences yet. Incidence if any will be added if needed. The wing is taped in place and a quick release similar to the Conscendo design will be added.

Flight tests to follow…….

Posted by VicT |

Mar 16, 2024 @ 09:54 PM | 5,449 Views

Used. My NX10 and made a copy of my Turbo Timber, renamed it Timber 2m and made the aircraft type 1 ail, 1 flap. B and D are flight modes. Bound the AR8036T RX that came with Geof’s model. Had to reverse elevator, aileron, and rudder. Motor works but at flight idle motor kept running and would only stop with throttle cut. Page 20 of manual states that throttle trim should be mid point. Did this and prop stopped turning. This is not obvious and is surprising.

Checked out trim in flight. Had to change elevator compensation. Does nice SAFE spins and crosswind control low passes. Glide is nice and made 4 or 5 landings and takeoffs. On last landing wind was WSW 8 and a downburst made the model hit hard in the grass. Impact tore the landing gear away from the fuselage, ripped the Monocote and broke a prop. Southwest wind at altitude is not a problem but no model can escape the wind shear rotors when wind is from West and develops rotors from the pit facility.

Manual says motor is 14 poles.

Velcro straps too long, Foam spacer could be used for 6S lipo compression then cinching with velcro.

Vario on a switch as well as altitude could be put on C0,1,2

A retractable CG/hoist handle would benefit this larger heavier Timber.

Posted by VicT |

Mar 07, 2024 @ 07:19 PM | 4,000 Views

I flight tested my UMX Conscendo 2 before and after adding more rudder area and it makes a difference at low and high speeds. Not as much as I was expecting. I could get more angle by moving the rudder ball link to an inner hole like I did on Conscendo 1. The side areas of the fuselage are not enough to provide knife edge. A dedicated pattern type design would be needed similar to a flat plate foamy design. The added weight is between 1 and 2 grams. The plastic paper is from a Fedex Office and is called 2481 Sheet Card Stk 11x17. Cost is 40 cents.

Posted by VicT |

Mar 01, 2024 @ 08:08 PM | 5,542 Views

I am outfitting a 2019 Turbo Timber with floats for our Geotech fabric runway, and rough grass area. The floats prevent nose overs when throttle is advanced too quickly and the added contact width minimizes cross wind effects. However the grassy areas have uneven area and the staples that are exposed thru the fabric are hard to avoid. Sometimes the V bottom catches and upsets the sliding action of the floats. I have removed the front V shape of the Timber floats and this helps. In addition to lowering the center of mass the flat bottom improves “all terrain operation”. Floats can be used for water operation but are more usefull for land ops over the conventional landing gear. This is how…..

I extended the blade fully on a plastic box cutter and cut away the v bottom on the forward float areas. Then I used a 100 grit sandpaper board to smooth out the cut. I then covered the bottoms with vinal that is used for 8.5 by 11 inch paper. I used double sided rug tape to secure the plastic to the foam bottoms. I weighed the blue and white Timber with a 4S 2200 pack and she is much lighter than the latest red and white Turbo Timber Evolution by almost 30 percent! I like flying the heavier Evolution and the twin Timber but the older design flys much slower because of the lower wing loading. See the pics for more info

Posted by VicT |

Feb 21, 2024 @ 08:05 AM | 6,647 Views

This model can get difficult to see after a few seconds of full power. I use a streamer that is about 12 ft long and taped it on to the rudder. It reflects the sun and the flashes can be seen much further away than the model. I use two strands from metalic tinsel foil that is used as a curtain for a prop when taking photos. The material is strong, light, and I recently flew for 17 minutes on a 3S 300 lipo. Loops and other aerobatic maneuvers are easier to see. I wrap it up on a piece of cardboard and store it in the Conscendo box.

Posted by VicT |

Feb 14, 2024 @ 07:43 AM | 5,883 Views

Clubmember Dan B just acquired a used AL57 and asked for some help prior to the maiden. Previous owner did not use SAFE but the new owner selects SAFE Off only for rolls and loops. He has two AR637TA receivers and I installed one to program correct movement of flight controls, gear and SAFE Select switch B on his NX8 transmitter. He has two Avian 70 amp ESC units that came out of two Habu SS jets and he is proficient at using their reverse thrust program. Both require TX programming using AVIAN menus for rotation, brake force, channel activation and mixing using I button similar to Habu program. A Lazy Susan table would be nice to see asymmetric thrust thru out the throttle range. Wheel chocks on the plywood table would be required. Table should be staked to the ground. Differential thrust could be programmed and checked on the table if wanted for tight turns on ground or in flight.

The existing ESC’s do not have reverse thrust but do have a Y harness from both ESC that connect to a single EC5 connector for the 6S flight pack. A harness will have to be soldered up since I could not find one to purchase. A foam scrub brake taped between the two nose tires will act as a rolling brake for the maiden. If after the trim/test flight the new owner wants reverse then the ESC’s will be soldered up similar to the stock harness using the stock harness but soldered up to the Avian 70A units.

Notes from Hobby Squak and RC groups include:

Check nacelles for loose connection to wing.

Check upper wing cracks for hard landings. Take pic for before and after comparison guide.

Check elevator, aileron, and rudder throws IAW with manual with SAFE On and Off (Self Level and Manual audio flight modes)

Check CG . Fingers on bottom are Ok but CG mark on top of wing must be verified and transferred to bottom of wings for accuracy.

RC car bushing oil to reduce wheel noise and wear/tear.

Posted by VicT |

Feb 08, 2024 @ 07:11 AM | 8,107 Views

After sitting idle for 20 years or so a club member maidened her with a Surpass 70 4 stroke. He said she had too much power. On landing a Robert copy cat retract broke. He gave it to me for electric conversion.

Old Cirrus servos especially elevator will be replaced and a 637T SAFE Select RX will be installed. No flaps so an Avian 45 ESC will be used for flight idle reverse thrust. Initial power will be a system used in a ASW17 2.5 m motor glider that weighs 5.1 lbs. estimated RTF weight is 5 lbs for 125W/lb.

Specs: 57” span, 605 squares, servos: 2 Cirrus aileron, 1 elevator, 1 rudder, 1 retract. Mostly balsa and ply with plastic canopy and cowl. Red/blue/yellow Monocote? covering. Tail wheel and rudder pull pull system.

...Continue Reading

Posted by VicT |

Feb 05, 2024 @ 12:55 AM | 7,487 Views

When buddy boxing pilots on new or unfamiliar electric aircraft I verbally coach them on the use of throttle. When they are going too fast I tell them to reduce throttle. Sometimes they have the throttle too low for the phase of flight and I tell them to increase throttle. If they go to “flight idle” or “cut the throttle” and are turning onto final I either have to take control to avoid a stall or hope that they respond quickly to avoid a stall. In the future I’m sure we will have a pitot tube type of sensor that will be programmed to alert pilots of an impending stall. Maybe it will increase the throttle automatically to maintain minimum control speed. Until then we learn from the individual model’s performance and speed to judge throttle correctly. With motor gliders throttle is usually used on climb and then not used. Pilots transitioning to motor gliders often do not bring the throttle to flight idle and the motor is draining the battery and the prop is causing windmilling drag. The use of a rubber band on the throttle stick can avoid this problem.

I have been using bungee type rubber for all sorts of applications. However the clear rubber bands from Goody have been my favorite for my motor gliders. They offer an additional use in avoiding prop strikes when using throttle cut on our transmitters. Unlike most small rubber bands they seldom break and can be permanently lengthened to fit the desired tension.

...Continue Reading

Posted by VicT |

Feb 02, 2024 @ 07:14 AM | 5,365 Views

Some RC aircraft models are designed without a rudder to reduce complexity, weight and cost. If you depend upon rudder for certain phases of flight then the absence of a rudder can be frustrating. After test flying a popular model with fixed gear I added a nose wheel fairing to provide yaw control. It’s made from clear plastic and is held in place with clear tape and thread. Size and shape can be finalized after getting experience. In flight it helps in low or high speeds. See the photo to get a better idea.

Posted by VicT |

Jan 26, 2024 @ 07:42 AM | 5,615 Views

I don’t know of any RC transmitter that has auto-throttles for takeoff. Autothrottles are used on take off for full size aircraft especially for turbine type aircraft such as the DC10, Airbus 300/310, and Boeing aircraft. However Throttle Delay is similar and is available on most Spektrum transmitters.

My oldest TX is the DX9. The 2013 manual does not describe how to use the throttle delay or its purpose. In the Function Menu scroll down 3 lines to Throttle Cut and press the roller. A monitor is on the left and on the right is Throttle Cut. Use the roller to scroll to Inhibit and press to get Inhibit to flash. Now you can select a switch. I use the H switch as once I start flying my right hand is busy with aileron and elevator and I don’t want to take my fingers off the right stick. After selecting a switch you can see how it works with out powering up your electric motor or 2 stroke/ 4 stroke engine. If you set the delay to 5 seconds it will only work once and after that the throttle will not have any delay. Here are just some of the purposes of throttle delay.

1. It avoids throttle jamming or throttle bursting on the engine or motor and causes less stress on the motor and airframe.

2. It automatically accelerates rpm from 0 to max rpm in 5 seconds or so. My 5 second delay is actually almost 6 seconds but is constant.

3. It avoids having to use your thumb to move the throttle stick up and the rudder stick left or right at the same time during the take off.

4. When throttle cut is used and is accidentally uncut if the motor accidentally starts turning you have 5 seconds to get out of the way to reduce the throttle or re cut the throttle.

For trike or taildragger models where invisible forces cause yaw the 5 second delay allows concentrating on rudder to keep the model on a constant heading on the ground and after airborne.

You may think you don’t need it but it reduces pilot workload and takeoffs get easier safer and more enjoyable.

Posted by VicT |

Jan 24, 2024 @ 12:33 AM | 6,156 Views

I like both the Habu SS 6S and Habu STS 4S. They are simple trainer jets that work good before going on to more advanced designs. The STS DXS TX is OK but the RX/controller is locked and more advanced features are not available unless you replace with a 637T, Avian ESC, and NX6 TX. The fan motor works great with a 3300 4S and my maiden flew 9.5 min. With mixed flying styles. Reverse thrust stops the STS in 50 ft with a 10 mph cross on Geotech RWY. On the last landing I used more reverse thrust after a bounce and broke the left main strut. I tried to bend it but it separated so I removed all trike gear and hand launched with a 2200 4S. Later I took off by sliding into the 10 mph wind across the 45 ft wide Geo fabric with no belly vynal sheet like I use on floats. Telemetry max amps was about 67 so an Avian 60-100 amp ESC can work. The 100 Amp ESC installed will be tested with a 6S.

The best feature of this STS mod is her gliding performance. I reduced elevator throw to mid rate 85% to avoid power off full up stall and rudder only was used for approach and go around phases, CG hoist works great for different flight packs. I flew until LVC when pulsing was heard after my deadstick slide landing.

More practice can create quite a routine showing the low weight performance.

Posted by VicT |

Jan 24, 2024 @ 12:10 AM | 6,090 Views

1/23/2024 Bob Aguis agreed to let me show and sell Tom Jacobs Leader 480. Dave Anderson let me fly his and performance was like a small pattern design. I inspected Bobs Leader and removed the old Futaba RX and removed the wings. Fuselage wood was broken and repair wood had been added.

Dave’s restoration includes a Badass motor, 10/6 prop, 2200 4 S see pics

Posted by VicT |

Jan 20, 2024 @ 12:11 AM | 6,618 Views

I soldered a JST on to the RDQ 300 4S so that I could use the 4 other packs that have JST. The canopy barely fits!

Note the increase in telemetry data.

Posted by VicT |

Dec 24, 2023 @ 06:23 AM | 5,092 Views

The UMX Conscendo has so much going for it in the stock untouched version. I will be using her for buddy box training for 50 mm EDF designs since typical new pilots that join our club want jet speed. However for taxi, takeoff and landing land floats offer good training.

I like the looks of float planes and they are fun to skid around on the ground/runway like an airboat. They fly about the same since most of our electrics are over powered. The floats add side area so knife edges are easier. Floats protect the prop and can minimize nose overs that can damage the top structures. Water landings and takeoffs are challenging especially if one float causes drag and causes cartwheels. I select SAFE since the sensors are better than my depth perception for leveling the wings/floats.

The photos show the concept using my Turbo Timber UMX floats. Packing tape protects the belly and stickier Duck tape will secure the floats for flight testing. When I figure the best fore/aft location they will be plug in using old credit card plastic.

Background:

When reversing speed controls were available I used them on my Maule. However the taildragger design worked but max effort straight line braking was a challenge. When I added wheels to the floats it became much easier and more fun. I added a mix so when I pushed the button a low rpm was set for a slow deceleration to a stop. Max throttle could be used if needed for panic stopping. Since then I’ve been using floats and

...Continue Reading

Views: 18

Views: 18  Views: 23

Views: 23  Views: 20

Views: 20  Views: 18

Views: 18  Views: 34

Views: 34  Views: 28

Views: 28  Views: 33

Views: 33  Views: 26

Views: 26  Views: 34

Views: 34  Views: 29

Views: 29  Views: 21

Views: 21  Views: 29

Views: 29  Views: 41

Views: 41  Views: 58

Views: 58  Views: 38

Views: 38  Views: 32

Views: 32  Views: 42

Views: 42  Views: 33

Views: 33  Views: 40

Views: 40  Views: 32

Views: 32  Views: 85

Views: 85  Views: 58

Views: 58  Views: 35

Views: 35  Views: 32

Views: 32  Views: 29

Views: 29  Views: 38

Views: 38  Views: 32

Views: 32  Views: 20

Views: 20  Views: 16

Views: 16  Views: 23

Views: 23  Views: 17

Views: 17  Views: 13

Views: 13