Comments (0)

Add Comment

-

Views: 844

Views: 844

1st place at the Gene Hays Memorial RES contest ISS Riverside June 12-11 -

Views: 1081

Views: 1081

-

Views: 1258

Views: 1258

Three piece wing top mount. -

Views: 1180

Views: 1180

2.4 friendly fuse. Will be pre painted in the mold White. -

Views: 1129

Views: 1129

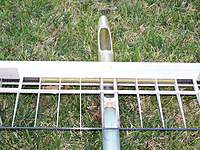

Built up Elevator and rudder. -

Views: 1244

Views: 1244

-

Views: 1255

Views: 1255

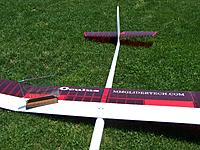

Kevlar rapped spars -

Views: 1289

Views: 1289

-

Views: 519

Views: 519

Main top. -

Views: 407

Views: 407

Main bottom. -

Views: 438

Views: 438

Set the root. -

Views: 400

Views: 400

-

Views: 433

Views: 433

Splash for new skin. -

Views: 425

Views: 425

-

Views: 400

Views: 400

Scarf the skin surface. -

Views: 411

Views: 411

Note that the glass on the inside is dry. This is what makes for the light layups. It also makes it easy for the skin to delaminate.