Comments (0)

Add Comment

-

Views: 95

3D Printer Enclosure, Clico'd together. I know it looks light blue, but the interior is white. -

Views: 86

Views: 86

Cleco Pliers and Cleco clamps. -

Views: 110

Views: 110

Cleco's used to assemble wing structure for aircraft. -

Views: 90

Primary Distribution Module deck prior to painting. Two speaker boxes to the right. Secondary Distribution Module deck to the left. -

Views: 91

Secondary Distribution Module deck on right, Auxiliary Distribution Module deck on left, amplifier mount below. -

Views: 88

Primary Distribution Module, Negative Bus Bars Installed. -

Views: 86

-

Views: 109

Primary Distribution Module, Battery fuse block (HZ100) installed and three DC/DC converters installed.

-

Views: 125

Views: 125

Print at about 32:00 hours. -

Views: 140

Views: 140

Finished print. Sitting on my laptop keyboard (Octoprint on the screen). -

Views: 120

Views: 120

Finished print, looking down into the turret. Sitting on my laptop keyboard (Octoprint on the screen). -

Views: 104

Views: 104

Finished print, looking directly down into the turret. Stringy filaments are caused by the print head transitioning from one side to the other and the filament oozing out of the print nozzel. -

Views: 144

Views: 144

Finished print with part of the support material removed. Shows the depression rails better.

-

Views: 110

Views: 110

Dayroom Print once I stopped the printer. -

Views: 101

Views: 101

Shows distance vertically the print head moved but did not lay down any extruded material. -

Views: 109

Views: 109

Opposite side of print from what I have been taking each time when it was on the build plate. -

Views: 112

Views: 112

Starboard side view of partially compleate Dayroom. -

Views: 98

Views: 98

Port side of Dayroom. -

Views: 102

Views: 102

Bottom view in sunlight of dayroom. -

Views: 114

Views: 114

Think I will trim off the section above the red line (at the rib) and print a new part from there. Then glue them together.

-

Views: 97

Views: 97

I didn't capture the print height on this shot, Sorry. But is somewhere in the 260mm range. -

Views: 95

Views: 95

Dayroom Hatch (upper left "corner" of print) about 1/3 printed. Open hatch has support material (accordian printing) in the opening to support the horizontal frame (forward frame) of the hatch opening. -

Views: 97

Views: 97

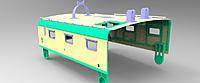

Rendering of dayroom CAD model sort of in orentation that I have taken all the printing pictures. When I remove all the support material from the compleated print, it should look like this. -

Views: 117

Views: 117

Rendering of Dayroom CAD model showing details on top.