Posted by H2SO4 |

Mar 20, 2012 @ 09:31 AM | 78,516 Views

Many people are aware of the potential health risks of asbestos. In its time, it was considered the wonder material for building all sorts of things, including houses, seeing as it was relatively cheap and impervious to most forms of chemical attack. Therein lies the problem - the stuff lasts forever. It is so chemically inert that the human body has no viable means of breaking it down. Even that wouldn't be a problem if it wasn't for the natural crystalline shape of the mineral - incredibly fine needles of rock.

When inhaled, the larger fibres, visible to the naked eye, are eventually removed by natural cleansing processes in the lungs. Truly tiny fibres are wholly encapsulated and thereby removed by specialised blood cells. It's the ones in between that can kill.

There's a particular length that is too small to be expelled but too large to be encapsulated. Those fibres end up forever stuck in a person, subtly irritating the lungs themselves and potentially the pleura - their lining. Over many years, such constant irritation can develop into asbestosis, a reduction in lung capacity caused by scarring, or even mesothelioma - one of the most lethal of all cancers. Thankfully, not everyone who's been exposed to asbestos will die from it, and stories abound regarding individuals who've metaphorically smoked the stuff in a bong for half a century with no ill effect, but individual exceptions do not a case disprove. Hundreds of thousands of workers have been exposed to...Continue Reading

When inhaled, the larger fibres, visible to the naked eye, are eventually removed by natural cleansing processes in the lungs. Truly tiny fibres are wholly encapsulated and thereby removed by specialised blood cells. It's the ones in between that can kill.

There's a particular length that is too small to be expelled but too large to be encapsulated. Those fibres end up forever stuck in a person, subtly irritating the lungs themselves and potentially the pleura - their lining. Over many years, such constant irritation can develop into asbestosis, a reduction in lung capacity caused by scarring, or even mesothelioma - one of the most lethal of all cancers. Thankfully, not everyone who's been exposed to asbestos will die from it, and stories abound regarding individuals who've metaphorically smoked the stuff in a bong for half a century with no ill effect, but individual exceptions do not a case disprove. Hundreds of thousands of workers have been exposed to...Continue Reading

Comments (4)

Add Comment

Posted by H2SO4 |

Dec 08, 2011 @ 09:07 PM | 79,687 Views

I'm now officially 3D-obsessed. While I completely respect everybody's right to enjoy other aspects of the hobby, to me 3D is the finest manifestation of RC splendour, and I find it downright mesmerising to watch a 3D plane being put through its paces by a good pilot.

My current objective is a decent torque roll. For those not familiar, a torque roll is a (much) more difficult version of a hover. Since 3D planes generally have 2:1 power-to-weight ratios, it is relatively easy to "hang the plane on its prop" and have it dangle vertically underneath in a static hover. With the right airframe (lots of propwash over large ailerons, massive control surface throws), hovering is easy and satisfying to learn.

Torque rolls build on hovers by allowing the propeller's toque to gradually roll the plane around on its long axis while hovering. "For every action there is an equal and opposite reaction", which means that the motor's attempt to swing the propeller clockwise also results in the rest of the airplane attempting to roll counter-clockwise, but this subtle effect is not normally discernible on a general purpose plane that is set up correctly.

Good pilots make torque rolling look simple, even in this example which I found on YouTube where the plane (a Multiplex FunCub) is not specifically designed for 3D:

While practicing torque rolls, I found that I have difficulty...Continue Reading

My current objective is a decent torque roll. For those not familiar, a torque roll is a (much) more difficult version of a hover. Since 3D planes generally have 2:1 power-to-weight ratios, it is relatively easy to "hang the plane on its prop" and have it dangle vertically underneath in a static hover. With the right airframe (lots of propwash over large ailerons, massive control surface throws), hovering is easy and satisfying to learn.

Torque rolls build on hovers by allowing the propeller's toque to gradually roll the plane around on its long axis while hovering. "For every action there is an equal and opposite reaction", which means that the motor's attempt to swing the propeller clockwise also results in the rest of the airplane attempting to roll counter-clockwise, but this subtle effect is not normally discernible on a general purpose plane that is set up correctly.

Good pilots make torque rolling look simple, even in this example which I found on YouTube where the plane (a Multiplex FunCub) is not specifically designed for 3D:

| Torque Roll con FunCub por Jose María Avecilla. (0 min 41 sec) |

While practicing torque rolls, I found that I have difficulty...Continue Reading

Posted by H2SO4 |

Jul 18, 2011 @ 11:03 PM | 80,953 Views

My first RCG blog post. Given the number of clever people who congregate here, attempting to come up with something avant garde is not simple, especially when you don't actually know all that much, which happens to be my affliction.

Today's chosen topic is reducing the resistance to movement exhibited by foam hinges. Multiplex and many other manufacturers seem to be rather keen on this design, but I'll leave my "why?" speculation for the end of the post. First the "how?" bit...

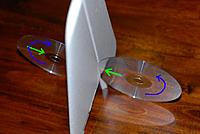

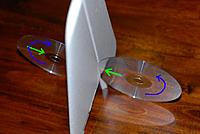

The tools are not very sophisticated - a couple of unwanted CDs or DVDs. The goal is to compress the foam bridge which links the wing/stabiliser to the moving control surface, thus reducing its resistance to bending:

Rotate the CDs while applying firm but controlled inward force. The edges of the CDs will be centred by the profile of the foam itself, but be careful to avoid running off the hinge and into the meaty part of the foam. There is little likelihood of that if the procedure is carried out slowly.

I find it easiest to control alignment when looking from the top - along the axis of the hinge - which helps me to ensure that the edges of the CDs pressing directly on each other:

In this instance the hinge continues all the way along to the edge of the vertical stabiliser, which makes it easy to use regular (round) CDs. If your hinge is bounded on two or three sides by the stabiliser, like the rudder and elevator respectively on a Multiplex EasyStar, it's...Continue Reading

Today's chosen topic is reducing the resistance to movement exhibited by foam hinges. Multiplex and many other manufacturers seem to be rather keen on this design, but I'll leave my "why?" speculation for the end of the post. First the "how?" bit...

The tools are not very sophisticated - a couple of unwanted CDs or DVDs. The goal is to compress the foam bridge which links the wing/stabiliser to the moving control surface, thus reducing its resistance to bending:

Rotate the CDs while applying firm but controlled inward force. The edges of the CDs will be centred by the profile of the foam itself, but be careful to avoid running off the hinge and into the meaty part of the foam. There is little likelihood of that if the procedure is carried out slowly.

I find it easiest to control alignment when looking from the top - along the axis of the hinge - which helps me to ensure that the edges of the CDs pressing directly on each other:

In this instance the hinge continues all the way along to the edge of the vertical stabiliser, which makes it easy to use regular (round) CDs. If your hinge is bounded on two or three sides by the stabiliser, like the rudder and elevator respectively on a Multiplex EasyStar, it's...Continue Reading

- User Lists