Posted by BigBRC1 |

Oct 19, 2015 @ 06:21 PM | 66,106 Views

Seven years ago, I built a Nitroplane's B-17 kit, my first 17. Since then, I've had six other 17's, mostly HK 1875mm epo's. I saw a kit at a swap meet at Apollo that my squadron mate Joe was selling, with no labels on the box. After looking it over, I was sure it was the same model. Will almost. This was a later version. On impluse, I bought it. Back then, scale was no big deal with me, but now! I wasn't sure I wanted to do all the moding required to even make it look somewhat scale. Anyway, here's the build/mod.

Posted by BigBRC1 |

Jul 27, 2015 @ 09:48 AM | 6,500 Views

Rather than wait for a maiden flight, I decided to go ahead with finishing off my 61 by spraying painting her with gloss black, top and bottom, keeping fairly true to scale photo references. But for inflight I.D., I added the works 'Black' on the right underwing and 'Widow'

on the left. Hopefully this will help in orientation. Taxi test look good, but the build needs some mods. on the wing to correct an incident angle and the main gears need to be moved further back to eliminate the nose gear bouncing. Not sure the time needed , but will post when complete.

Posted by BigBRC1 |

Jul 14, 2015 @ 06:32 PM | 6,440 Views

After spending more hours than I care to admit on my B-29 build, you'd think that I had had enough. But like the old saying goes, 'you can't eat just one peanut....'. Many months ago, I had seen some plans for a Northrup P-61 Black Widow on the internet. They were very simple with fixed landing gears and gas motors. The scale was to large, but showed N- rods for the control surfaces which interested me, since it eliminated servos, thus making the plane lighter. Since I'm an 'e' guy, I wondered if I could mod it. I had recently crashed a FMS Mosquito with a 55" wingspan and 4lbs, 9 0s fiying wt. Starting with all the Mossie electronics, I rescaled the plans to a 45" wingspan, figuring I could build a plane until the Mossie's weight and thus making it earier to transport since the wing wasn't detachable. Using Depron foam for formers, ribs and covering, plus some ply and balsa were strength was needed, I first built and complete jig. My main goal was too ' build it straight, strong and light'!

Posted by BigBRC1 |

Jul 14, 2015 @ 06:06 PM | 6,272 Views

"Hollywood" B-29 at Apollo Field in Van Nuys, CA for her first preview my the 'Warbirds Squadron'.

Posted by BigBRC1 |

May 03, 2015 @ 09:28 AM | 7,558 Views

The B-29 is coming along slowly. Had a nose gear retract go bad and haven't been able to get a replacement from Nitroplanes. So, have ordered a new from another course and hopefully it will work. I took the plane out to Apollo Field for a few taxi tests and it manuevers great. Will finish covering and will try some hi-speed tests soon.

Posted by BigBRC1 |

Mar 23, 2015 @ 09:53 AM | 7,215 Views

I've been working on my B-29 now since early December of last year. Its been quite an experience. Not having any guides or pass knowledge of building a plane from scratch, I did take on a whopper of a project! I've made many mistakes, some correctable and some not so correctable, but hopefully in the final analyst, she will be airworthy enough to at least get of the ground. I hoping in a week or so, I will be ready to try some taxi tests and maybe a take off roll to see if it will rotate.

Posted by BigBRC1 |

Feb 02, 2015 @ 10:28 AM | 7,006 Views

After taking my B-29 scratch build to Apollo Field for members of my Warbirds Squadron to review, the following comments were made. The elevator needs to be rebuilt 15% larger. I'm also going to replace the depron wing ribs with balsa ribs. And I need to check that the incidence angle is the same on both left and right wing. To strengthen the wheel well covers (which I made removeable for ease of access), I will fiber glass them. The attached pics show the elevator rebuilt using all balsa (no depron). Like the vertical fin, I figured the all balsa would be stronger. The 1/16" balsa mid-section I wicked first with thin CA before adding the ribs. I'll skin it with 3mm depron and cover it with Monokote Parklite Aluminum.

Posted by BigBRC1 |

Jan 27, 2015 @ 08:21 AM | 8,407 Views

To complete the tail section on my B-29 build, I fashioned the gunner's position out of balsa and lite ply. I'll insert a gunner figure after painting and installing some acetate windows. Now for the turret. Needing a ball shape, I found a ping pong ball. I cut it in half, cut out the shape for the guns and using the other half, placed it inside. Adding a piece of dowel , drilled two holes for guns and pivot hole, inserted a wire and I had a rear turret. I may attach it with a magnet so as not to damage it in transport.

Posted by BigBRC1 |

Jan 20, 2015 @ 09:44 AM | 8,550 Views

The last part of the empennage was the rudder fin. I got a few different ideas from modelers on the internet. Wanting to build it as close to scale as I could, I sketch my plan and the material I would use. With the ribs being a modified diamond shape, I had to build it ' in the air'. I used 2mm styrene for the hinge part and drilled a hole in one end into which I inserted and glued a piece of aluminum tubing. Next I inserted a piece of wire that fit snuggle and glued the wire to the balsa sheet base. Another piece of wire with a servo horn was glued to the place opposite the servo. Then both hinges were glued to the forward stab. Finally, a 'Z' bent wire was attached to the horn and the wire to the connectors on the servo. An access door over the servo will allow adjustments if needed.

Posted by BigBRC1 |

Jan 19, 2015 @ 01:16 PM | 7,608 Views

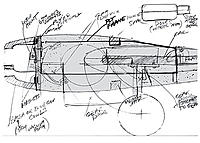

As I usually do and to see the build better, I sketched out the way I thought the assembly might look. My ideas have come from many model builder I saw on the internet. My thanks to all of them. All during the build, I have continuely change direct and saw a better way to do it. As for the elevator, my original plan was to place the servo directly under it. But in reexamining my plans, I saw that the rear belly gun turrent was very close to the L.E. So it was a natural to make a removable hatch with the turret attached. I then can adjust the linkage if needed. I also changed my mind about gluing the elevator to the fuse. Instead, I used four wood screws after gluing in two rails between the saddle. The fin will be done the same. No glue. Three' tongues' will insert into slots in the fuse and be attached with longer bolts into blind nuts. I will post photos of the actual build soon.

Posted by BigBRC1 |

Jan 12, 2015 @ 05:27 AM | 8,497 Views

I knew that the wing on a B-29 would have very high loading, so flaps were going to be a must. Searching the internet, I found a modeler who had used a very simple flap style. I downloaded the pictures, made my usual sketch and started the build. First I glued a piece of 1/32" ply to the top of the flap area. To keep it straight while I glue the ribs, I taped it into position. I then hot glued 6mm depron ribs to it and covered the area with 3mm depron. I decided to make the hinges out of 2mm styrene. I mast produced 16 double hinges by clamping a master to 15 other pieces. I did the same for the 8 single hinges. I first installed the inboard hinge and then the outboard in balsa blocks and glue them in with CA. By inserting a wire through each, I could lineup the other two. I did the same for the single hinges. All hinges will be bolted in place with a lock nut keeping them secure. Placing the operating servo was a bit harder. One of my flying at Apollo subjected that I attach a ball link connector to the flap. This enabled the connecting wire to move freely. I cut to much of the T. E. away, but will make it just a slot later.

Posted by BigBRC1 |

Jan 11, 2015 @ 10:04 PM | 7,857 Views

A few pencil sketches and lot of revisions finally let me decide how I was going to build the nose gear retract and stearing mechanism. At first I thought the retract need to be mounted horizontal to the ground. But the plan changed when I discovered that the sample oleo strut I had been using to build the main was exactly the right size to the nose retract. Since I couldn't bend the strut wire I had to angle the platform the retract is mounted to. I plan to build sort of a box affair out of 1 1/16" micro ply epoxied to two set of ribs made out of the same ply. It will be secured to two carbon fiber rods running from the nose to the wing saddle. It should be very strong. The strut was modified by cutting off a part of the outside tubing just below the grub screw. Then the rod was also cut to the length of the strut. A hole to the gear axle will be drilled and JB Welded in place. 1 1/2" wheel will be attched with wheel collars. To recap: The build started on Dec. 10, 2014 one month from yesterday. I've been keeping a journal including time spent and what's been worked on. Total hours so for: 46 1/2. If all goes well, I 'm estimating another month or so before shes ready for a taxi test and evaluation of my building abilities. I'll email my Warbirds Squadron at Apollo Field in Van Nuys, CA.

Posted by BigBRC1 |

Jan 11, 2015 @ 08:55 AM | 7,931 Views

As I usually do first, a sketch helped to visualize my idea. To fabricate the oleo, I bought a brass tube and a solid aluminum rod to insert into it. A piece of rod with a hole to the gear wire was glued in the top of the tub with JB Weld. A 3mm wide slot was cut in the tube, a spring inserted, a 3mm tap hole was made in the rod and a grub screw inserted. A hole for the axle was drilled in the rod and the axle JB Welded in place. Robart wheels were mounted and I'll use the smooth cover with a decal of the actual B-29 wheel attached.

Posted by BigBRC1 |

Jan 11, 2015 @ 08:24 AM | 8,112 Views

Since the No. 2 and 3 nacelles would house the retracts and be more complicated to build than No. 1 and 4, I decided to tackle them first. As I usually do, a few sketches to help me decided the build. Even after my original idea, I made many changes. Getting the wheel well opening the right size (for dual wheels) and the the retract rails in the right position took some trial and error. The nacelles themselves will be carved out of blue cor and attached with magnets for easier access to the retracts. I plan on adding doors with spring loaded hinges. Either an elastic string or a piece of shrink wrap across the opening will close the doors when the gear retracts (pic to come). For the cowls. I hoped I could get a friend of mine who can vacuum form parts to make cowls, but in the meantime, I carved four cowls out of blue cor. They will be attached to the firewall with magnets.

Posted by BigBRC1 |

Jan 11, 2015 @ 07:50 AM | 7,914 Views

My original plan for attaching the wing to the fuse was to glue in four small blocks of basswood with blind nuts, two front and two back. Having to try to figure how to get them in the right position, I modified the idea and instead used two longer blocks. This made the attachment points stronger and to further strengthen the saddle, I added carbon fiber rods.

Posted by BigBRC1 |

Jan 10, 2015 @ 06:32 PM | 7,732 Views

Since the wing is 75" in length and my work table is only a little over 5', I lucky had an 8' piece of board and straddle it across the table. Made a ply wing reinforcer, added carbon fiber rods the entire length of the wing and epoxy the two halves together. My gig to support the wing tips was crude, but it somehow worked. The wing is straight.

Posted by BigBRC1 |

Jan 10, 2015 @ 06:19 PM | 7,469 Views

Since my main idea was to build as light as possible, I made the wing mostly out of depron. But is soon became obvious that it wasn't going to be strong enough.

Posted by BigBRC1 |

Jan 10, 2015 @ 05:43 PM | 7,960 Views

Excuse me if you see the post of another page (I'm still learning how to post), but I needed to keep the end goal in mind by creating a new nose art. To honor my dearly departed wife, Pat (nick name 'Patou'), I decided to mod the plane I had decided to model it after, 'Humpin' Honey' by putting my wife's head on the Vargas illustration and renaming her 'My Pinup Girl', Miss Patou. So, but to the build... Having had five HK B-17's with plenty of spare parts and knowing the ins and out of the plane (after many crashes), it was a natural to use the design of the B-17 to help with building ideas. I started with the easiest part, the elevator. It gave me a chance to try using 3mm depron to cover it. It became obvious that a pattern was necessary so as not to waste material. Early on, the plan not to have external wires leading from control horns to servos. I glued a servo horn to the center wire ( see black circle) and will mount the servo about 6" forward and slightly down. An access door will allow adjustment when necessary.

Posted by BigBRC1 |

Dec 13, 2014 @ 09:16 AM | 9,127 Views

After building and flying many B-17's from the new micro to HK's 1875 mm and after looking at what's left of my first crashed B-17 ( only the 63" wing and part of the tail assembly remains) for some time, wondered if I could convert it two a B-29. But after much searching the internet for plans and seeing that a B-29 looked a lot different than a B-17, except for the tail assembly, I decided to put together (piece meal) my own plans . The plane will have a 75" wingspan and be built mostly from Depron foam and balsa. It will have retracts, motors, ESC's, servos, etc. from my 'boneyard' of B-17 spare parts. I hoping flying weight will be in the range of 6 lbs. (like the HK B-17). I'll try to post photos of the build as I go along. To kick things off and knowing that I think much better with a pencil in hand, I sketched a idea of how I thought the plane would be built. At least, it was a beginning....

Update. As of today, Jan. 21, 2015 with the B-29 almost finished except to the tail gunner position and the vacuum formed cockpit and nose canopy and covering with Monokote Parklite, she weighs in at 6 lbs, 6 oz. To finish it completely, I guessing she will weigh under 7 lbs. My target weight was 6 lbs. 8 oz. when I started.

Posted by BigBRC1 |

Jan 21, 2014 @ 10:53 AM | 7,945 Views

My HK No.5 B-17 "Miss Patou 5" is now flying and as they say, 'Practice makes perfect' or in my case, practice makes flying better and easier. I've made mods such as extending the access area in the cockpit area by cutting out about 10" behind the cockpit and gluing the two parts together. It's held in place by two earth magnets mounted where the fuse is reinforced with a partial rib. This was necessary because all of the electronics and a MrRCSound card are mounted in the center top of the wing. Attaching the wing requires only plugging in the elevator and aileron leads. Since I using a separate battery to power the receiver, this makes plugging in the power sources to motors, receiver and sound card a snap and also helps in checking that the receiver and satellite lights are solid. The plane also has a different paint scheme than No. 4 with new decals.

Views: 170

Views: 170  Views: 164

Views: 164  Views: 174

Views: 174  Views: 189

Views: 189  Views: 173

Views: 173 Views: 177

Views: 184

Views: 162

Views: 162  Views: 172

Views: 172  Views: 169

Views: 169  Views: 169

Views: 169 Views: 211

Views: 208

Views: 257

Views: 191

Views: 191  Views: 265

Views: 265  Views: 182

Views: 182  Views: 244

Views: 244  Views: 212

Views: 212  Views: 220

Views: 220  Views: 245

Views: 245  Views: 281

Views: 281  Views: 187

Views: 187  Views: 206

Views: 206  Views: 177

Views: 177  Views: 216

Views: 216  Views: 173

Views: 173  Views: 182

Views: 182  Views: 189

Views: 189