Archive for September, 2014

-

Views: 823

Views: 823

Figure 1: Enable all servo throw. The servo should now move about + - 50 degrees from endpoint to endpoint. -

Views: 1249

Views: 1249

Figure 2: Fix aileron in the full up position. -

Views: 1329

Views: 1329

Figure 3: Using the transmitter, bring servo to the end point that corresponds to full up. Adjust and hook up linkage to servo and aileron, while the aileron is fixed as shown in Figure 2. -

Views: 1311

Views: 1311

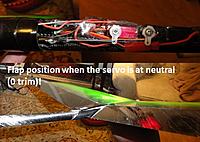

Figure 4: If you bring the aileron servo to neutral on the transmitter (0 trim position), the flaps are already partially down-deflected. This is the geometric middle of the total flap travel. Landing flap will be ~three times more down deflection. -

Views: 1109

Views: 1109

Figure 5: Use the trim menu to adjust the camber of the flaps. It takes about 30% to bring the flaperons to 0 degree camber in this example. On Futaba Trim Mix is a good menu to do that. -

Views: 791

Views: 791

Figure 6. Servo arm at forward endpoint corresponding to full aileron up.

Comments (5)

Add Comment