Archive for January, 2008

-

Views: 305

Views: 305

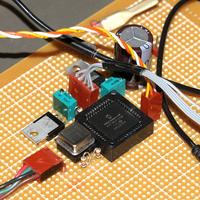

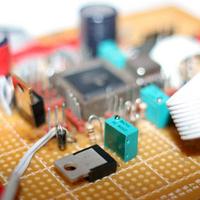

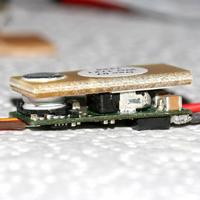

Your first look inside the CC BEC. -

Views: 271

Views: 271

It's mostly a heatsink, inductor & capacitor. -

Views: 248

Views: 248

-

Views: 283

Views: 283

Part numbers have been removed to prevent copying, but clearly it's 2 MOSFETs, a standard buck controller, & the reverse current diode. -

Views: 265

Views: 265

Inductors had a renaissance in the last 8 years because of energy shortages. -

Views: 264

Views: 264

-

Views: 256

Views: 256

-

Views: 256

Views: 256

Comments (1)

Add Comment

-

Views: 305

Views: 305

HS-65 metal gears 4 U. -

Views: 275

Views: 275

They do not come with a ball bearing, the world's smallest in fact. -

Views: 288

Views: 288

Took 2 hours to get the ball bearings transferred. -

Views: 288

Views: 288

-

Views: 271

Views: 271

Pot is right against the gears. No grease soaking this time. -

Views: 273

Views: 273

-

Views: 299

Views: 299

What U get after a few minutes of HS-65 punishment. -

Views: 303

Views: 303

The Jesus monitor meets the gears.

-

Views: 279

Views: 279

Snow on Missionary peak was the lowest we've ever seen it. -

Views: 239

Views: 239

-

Views: 235

Views: 235

-

Views: 236

Views: 236

-

Views: 225

Views: 225

The East side of Missionary peak -

Views: 236

Views: 236

The East side of Missionary peak -

Views: 226

Views: 226

Where we are most of the time instead of flying. -

Views: 246

Views: 246

Green tech is big, just not jobs in green tech.

-

Views: 361

Views: 361

What happens after a runaway copter in a dumpy apartment. -

Views: 306

Views: 306

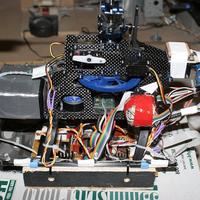

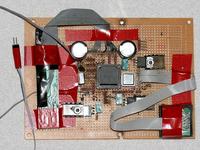

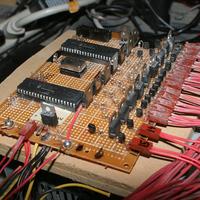

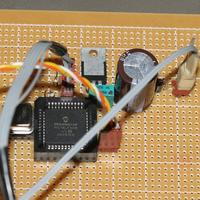

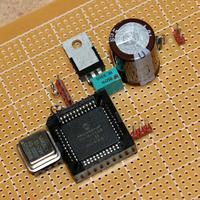

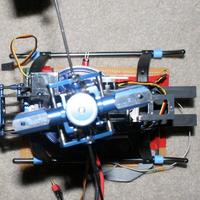

Vicaglider's current form in the programming harness. She's old fashioned, through holed, & point 2 point, but how else can U build a computer in a day for $10? -

Views: 340

Views: 340

Every 6 months, someone takes our $92,000 parking space so we have to park far away from the dumpy apartment. This time it was an executive, but not only can he only afford a 3 series, but it doesn't have a real alarm. -

Views: 282

Views: 282

Vicaglider without programming harness. -

Views: 292

Views: 292

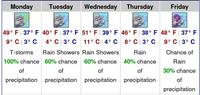

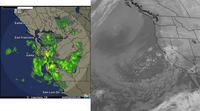

The Winter pattern.

-

Views: 340

Views: 340

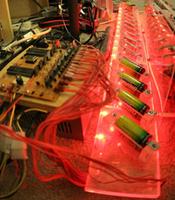

Another 4 hours of work between commutes. -

Views: 263

Views: 263

The Mega shaft is too short for the Taiwannosaurus. -

Views: 303

Views: 303

We have a hack for this problem, but no hex wrench is long enough to reach down there. -

Views: 303

Views: 303

Your first up close look at Karbonite. -

Views: 297

Views: 297

No engine tests can begin until the electronics R mounted, but clearly the Corona's shoes were a bit 2 big for the Taiwannosaurus. -

Views: 265

Views: 265

Taiwannosaurus tries again unsuccessfully. -

Views: 269

Views: 269

And again. -

Views: 245

Views: 245

There might be a way if she can stand off the board. The interconnects R in the way.